¶ Introduction

The International Occupational Hygiene Association (IOHA) refers to occupational hygiene as the discipline of anticipating, recognizing, evaluating and controlling health hazards in the working environment with the objective of protecting worker health and well-being and safeguarding the community at large. The term "industrial hygiene" stems from industries with construction, mining or manufacturing and "occupational hygiene" refers to all types of industry such as those listed for "industrial hygiene" as well as financial and support services industries and refers to "work", "workplace" and "place of work" in general.

Strict and rigorous scientific methodology is used and often requires professional judgment based on experience and education in determining the potential for hazardous exposure risks in workplace and environmental studies. Occupational hygiene is both an aspect of preventative medicine and in particular occupational medicine, in that its goal is to prevent industrial disease, using the science of risk management, exposure assessment and industrial safety. Ultimately professionals seek to implement "safe" systems, procedures or methods to be applied in the workplace or to the environment.

A Similar Exposure Group (SEG), also known as Homogenous Exposure Group (HEG) can be defined as:

a group of workers having the same general exposure profile for the pollutants/agent(s) being studied because of the similarity and frequency of the tasks they perform, the materials and processes with which they work and the similarity of the way they perform the tasks. (Mulhausen et al, 1998)

The purpose of Dynamics 365 HSE HEG is to formally and systematically support health exposure assessment as the foundation of preventative and protective health practice for its businesses.

The process relies on a competent occupational hygienist to conduct walk-through occupational hygiene surveys, group workers with similar potential exposures, devise and conduct exposure sampling programs and then to statistically analyze the exposure data.

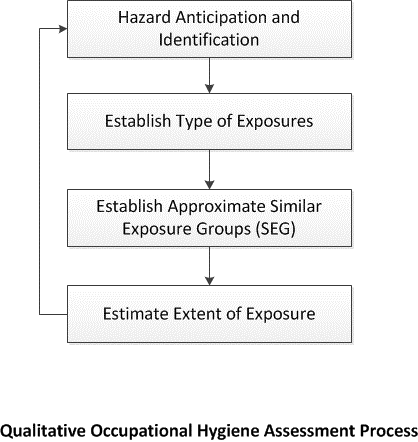

Essentially the hygienist is required to conduct and evaluate two types of exposure assessment:

- Qualitative Assessment - which is the basic characterization of exposure based on interview, observation and simple measurement

- Quantitative Assessment - which is conducted in accordance with recognized exposure monitoring strategies.

Regardless of the type of assessment conducted, the hygienist must analyze the data obtained and produce a scientifically sound report and provide guidance, clearly indicating any requirements for further exposure assessment and interim risk mitigating measures.

Qualitative:

SEGs are determined according to an examination of the activities workers perform AND a subjective judgment on the expected similarity of their exposures. Exposure monitoring data are not considered in detail if at all.

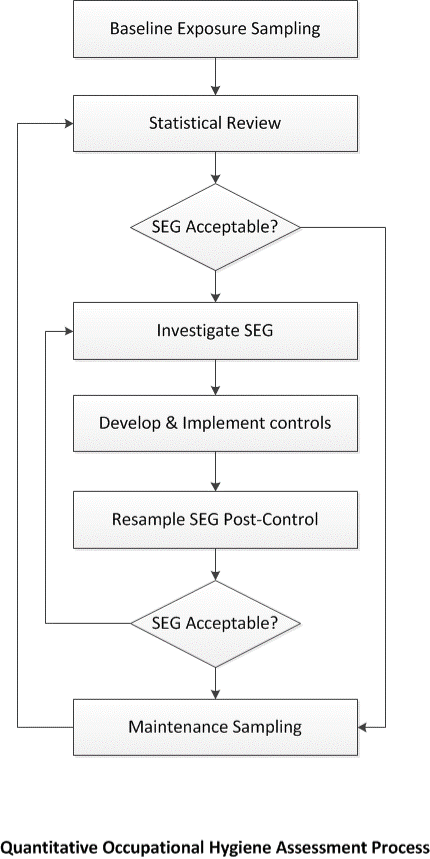

Quantitative:

“90th percentile” means the value which must be used to determine when HEG’s need to be reclassified.

This value can be calculated by:

- First placing all sample results in order from the lowest concentration to the highest concentration (i.e., concentration of specific contaminants).

- Next, assign each sample result a number, starting with the number 1 for the lowest concentration result up to the highest concentration being given the number equal to the total number of samples collected in that HEG.

- Multiply the total number of samples collected by 0.9.

- The sample result with the number corresponding to this calculated value = 90th percentile.

Terms/definitions

OEL - "Occupational exposure limit" means the time weighted average concentration for an 8 hour workday and a 40 hour work week to which nearly all workers may be repeatedly exposed without adverse health effects.

OEL - C - "Occupational exposure limit - Ceiling limit" means an instantaneous value which must never be exceeded during any part of the working exposure.

OEL-STEL - "Occupational exposure limit - Short term exposure limit" means a 15-minute TWA exposure which should not be exceeded at any time during a workday even if the 8-hour TWA is within the OEL-TWA. Exposures above the OEL-TWA up to the STEL should not be longer than 15 minutes and should not occur more than four times per day. There should be at least 60 minutes between successive exposures in this range. An averaging period other than 15 minutes may be recommended when this is warranted by observed biological effects.

For those substances for which no OEL-STEL have been specified, excluding airborne particulates, a figure of three times the occupational exposure limit is to be used when controlling short-term excursions in exposure.

"Respirable particulates" means the respirable fraction of airborne particulates.

"Inhalable particulates" means airborne particulates as collected by a personal gravimetric sampler without particle size selection.

¶ Navigation

¶ Security Roles

| Security Role | Duties | Privileges |

| Occupational hygiene administrator |

|

|

| Occupational hygiene clerk |

|

|

¶ Specific Setups

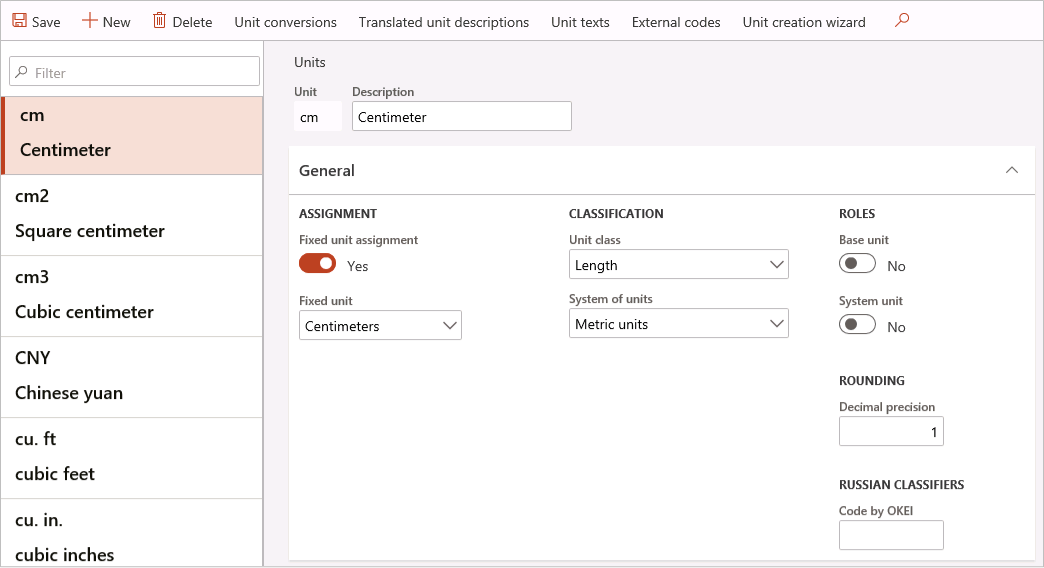

¶ Step 1: Setup Units

A unit of measurement is a definite magnitude of a physical quantity, defined and adopted by convention or by law, which is used as a standard for measurement of the same physical quantity. Any other value of the physical quantity can be expressed as a simple multiple of the unit of measurement.

Go to: Organization administration > Setup > Units >Units

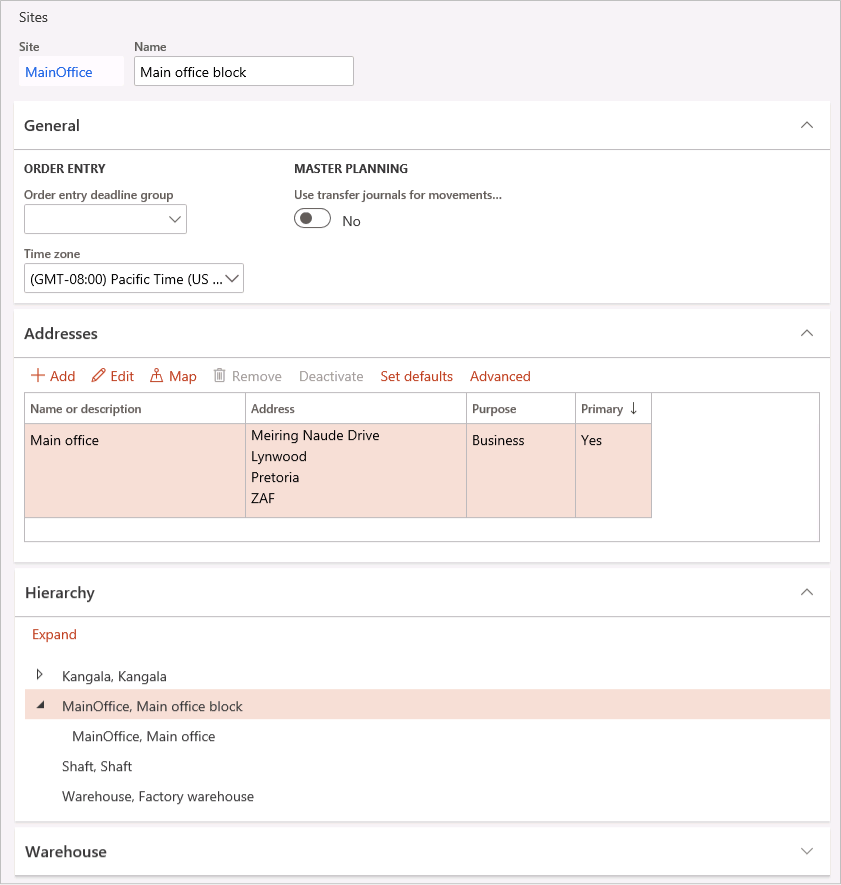

¶ Step 2: Setup Sites

The term site refers to a location at which a company has setup operations. A site is a grouping of resources and warehouses that are operationally interrelated. A site may be spread across multiple physical addresses, e.g. in the same city, if the associated resources and warehouse are operationally closely connected, and if it is considered one physical location.

From this perspective, an operational site can be considered the geographical location where items are stocked in warehouses associated with the site.

Go to: Inventory management > Setup > Inventory breakdown > Sites

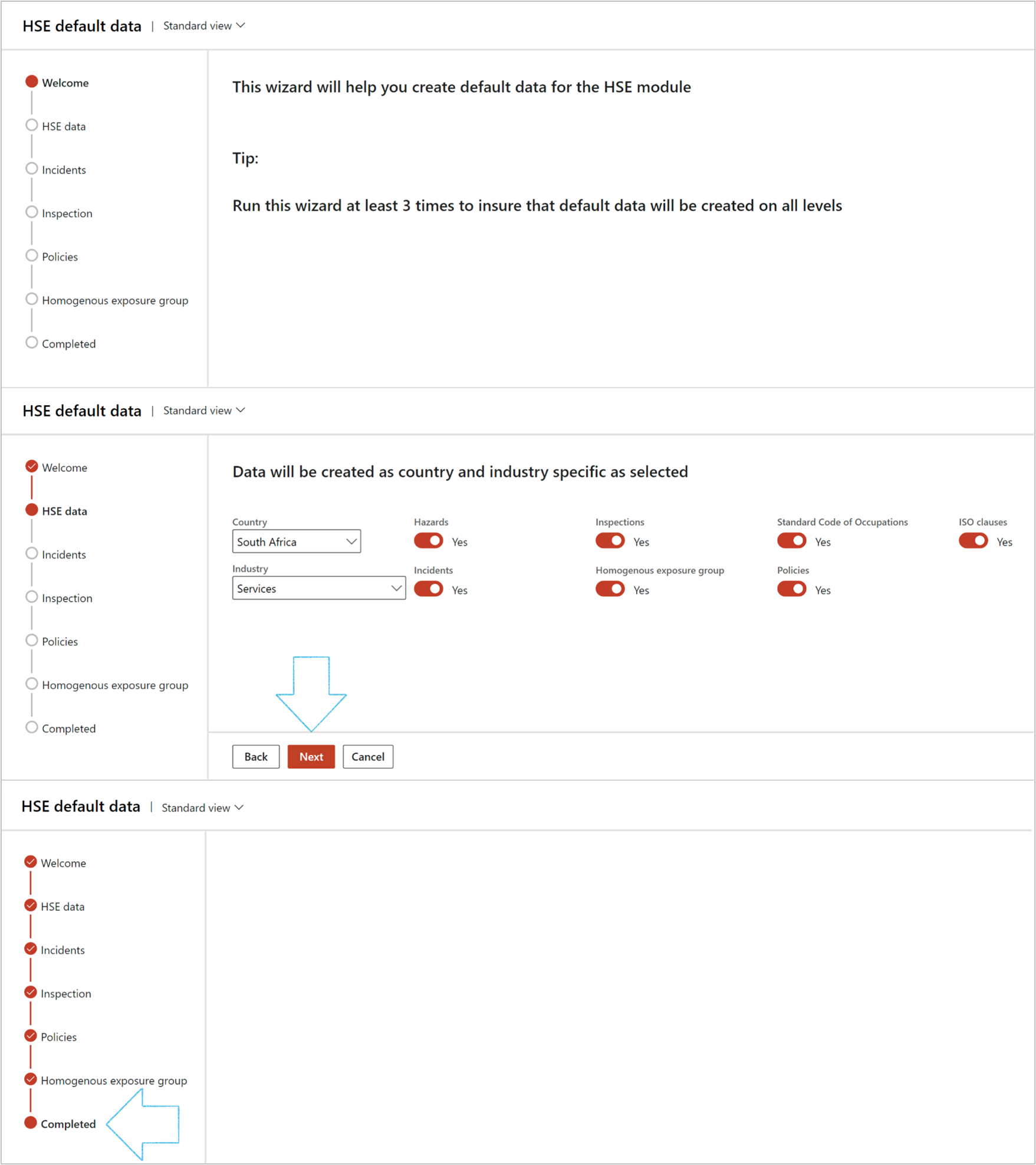

¶ Step 3: Using the Occupation code wizard

This is the occupation code list as set in the SANOHP codebook

There is a wizard available that the user can use to create the data.

Go to: Health, safety and Environment > Setup > Create local statutory content

- Click Next

- Select Yes for Standard code of Occupations

- Click Next

- Continue through all the following screens, making sure to select the relevant options

- Click Finish

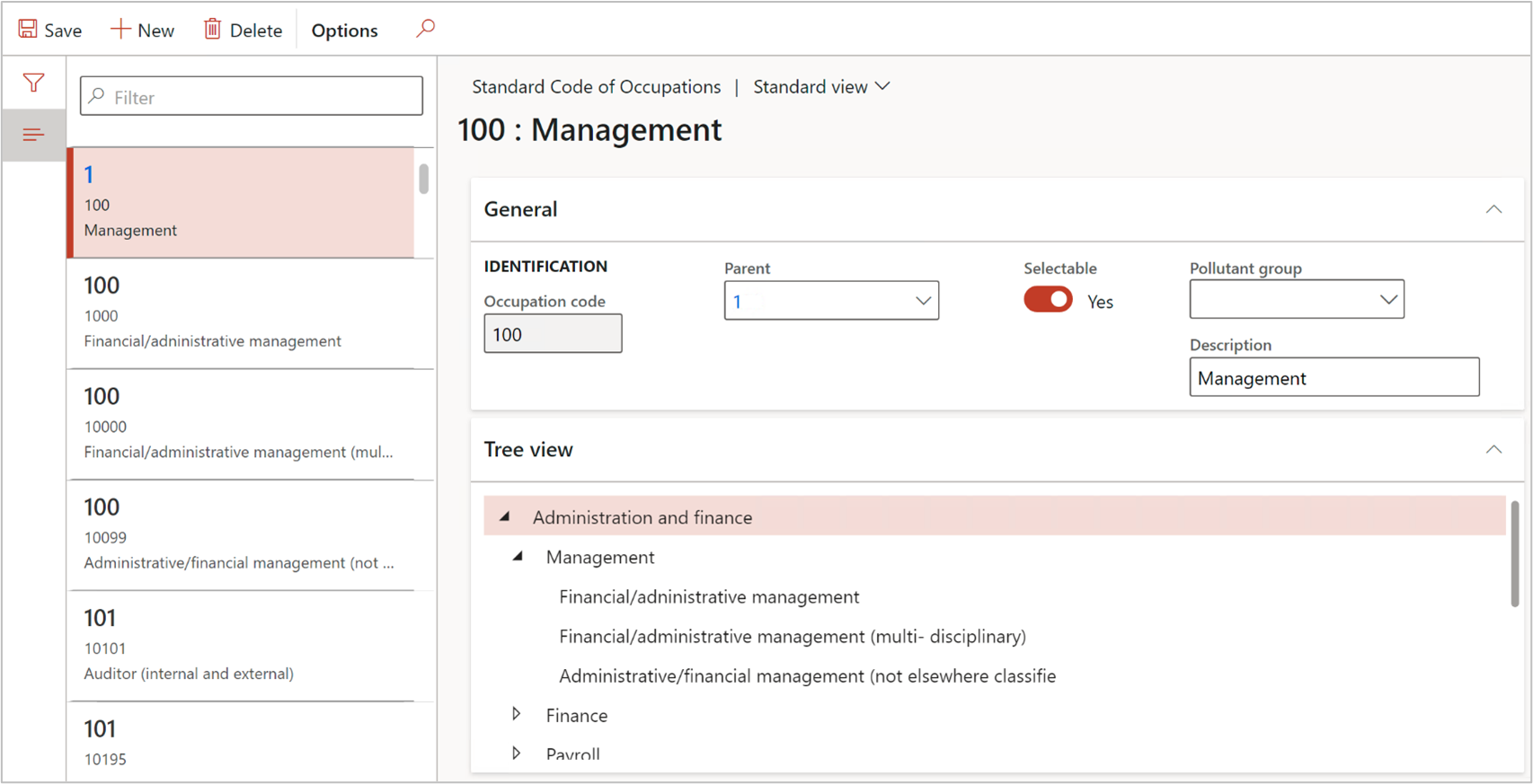

¶ Step 4: Standard code of Occupations

The Standard Occupational Classification (SOC) System classifies occupations. It is designed to cover all occupations in which work is performed for pay or profit. The 2010 SOC includes 840 occupational types.

Users of occupational data include government program managers, industrial and labor relations practitioners, students considering career training, job seekers, vocational training schools, and employers wishing to set salary scales or locate a new plant.

The SOC codes have a hierarchical format, so for example the code "15-0000" refers to occupations in the "Computer and Mathematical Occupations" category, and "15-1130" is a subset for "Software Developers and Programmers."

The SOC does not categorize industries or employers.

Go to: Health, safety and Environment > Setup > Standard Code of Occupations

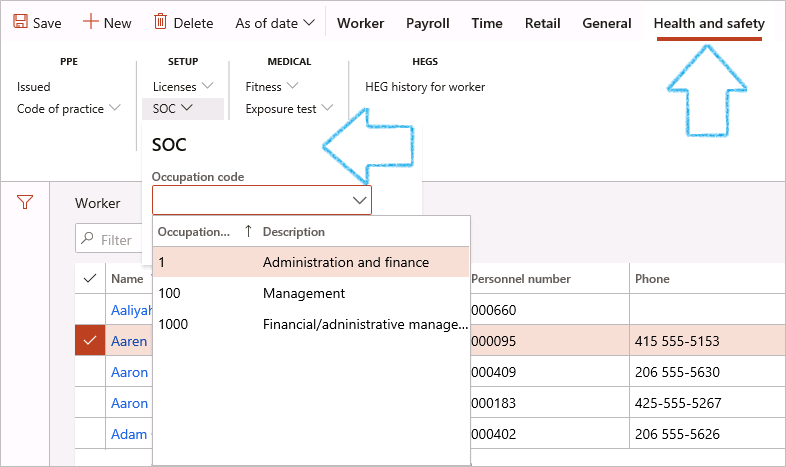

¶ Step 4.1: Link an Occupation code to a worker

Go to: Health, safety and Environment > Setup > Work force > Worker

- Open the Health and safety tab

- Select the relevant worker

- On the Action pane, in the Setup group, click the SOC (Standard Occupation Code) button

The SOC dialog will open:

- Select the relevant Occupation code (MISCO – Mining Industry Standard Code of Occupations) from the dropdown list

- Click OK

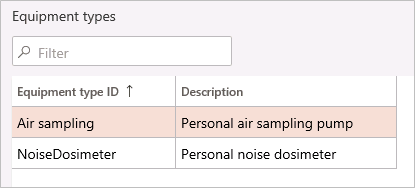

¶ Step 5: Setup Equipment types

This form is used to maintain equipment types. The types are used to group testing equipment.

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Equipment types

- To add an equipment type, click New

- Enter an Equipment type ID

- Enter a short description of the equipment type

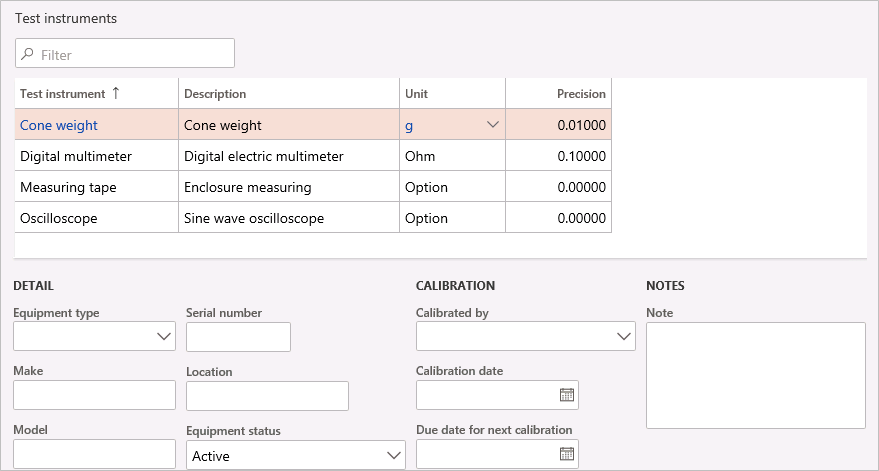

¶ Step 6: Setup Test instruments

Test instruments is a source for information about your test instruments, for example: Location, Calibration identification (serial number) and status.

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Test instruments

- On the Action pane, click New

- In the Test instrument field, enter the identifier for a test instrument

- In the Description field, enter a description for the test instrument

- In the Unit field, select the unit of measure for a test instrument

Units of measure must be defined in the Units form together with a decimal precision. The unit of measure applies to any test that is performed with the test instrument and the decimal precision applies to the acceptable test measurement values and to the reporting of test results

- The Precision field displays the decimal precision for the unit of measure, where the decimal precision has been defined

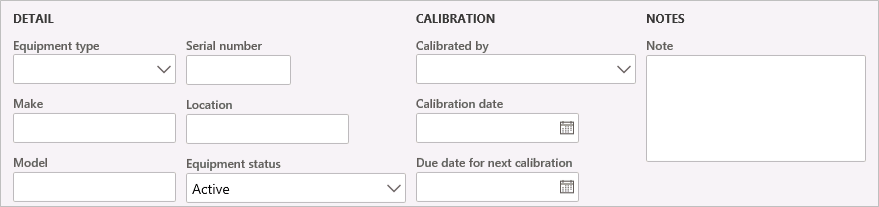

- Under the Detail field group, enter the following information:

- In the Equipment type field, select the relevant group from the dropdown list

- In the Make field, enter the manufacturer of the test instrument (used to identify a specific instrument)

- In the Model field, enter the model of the test instrument (used to identify a specific instrument)

- In the Serial number field, enter the serial number of the test instrument (used to identify a specific instrument)

- In the Location field, enter the location where the instrument is currently located

- In the Equipment status field, select one of the following from the dropdown list:

- Active – “Calibrated”.

- Inactive – “DO NOT USE - Out of Service”

- Discontinued – “DO NOT USE - Out of Service”

- Reference only – “NOT CALIBRATED – For Reference Only”

- No calibration required – “No Calibration Required”

- Lost – “Lost”

- Under the Calibration field group, enter the following information:

- In the Calibrated by field, select the person or organization that calibrated the instrument

- In the Calibration date field, select the date that the instrument was calibrated on

- In the Due date for next calibration field, select the date that the instrument is due to be re-calibrated

- In the Note field, optionally enter or view notes about the test instrument

- Click Save

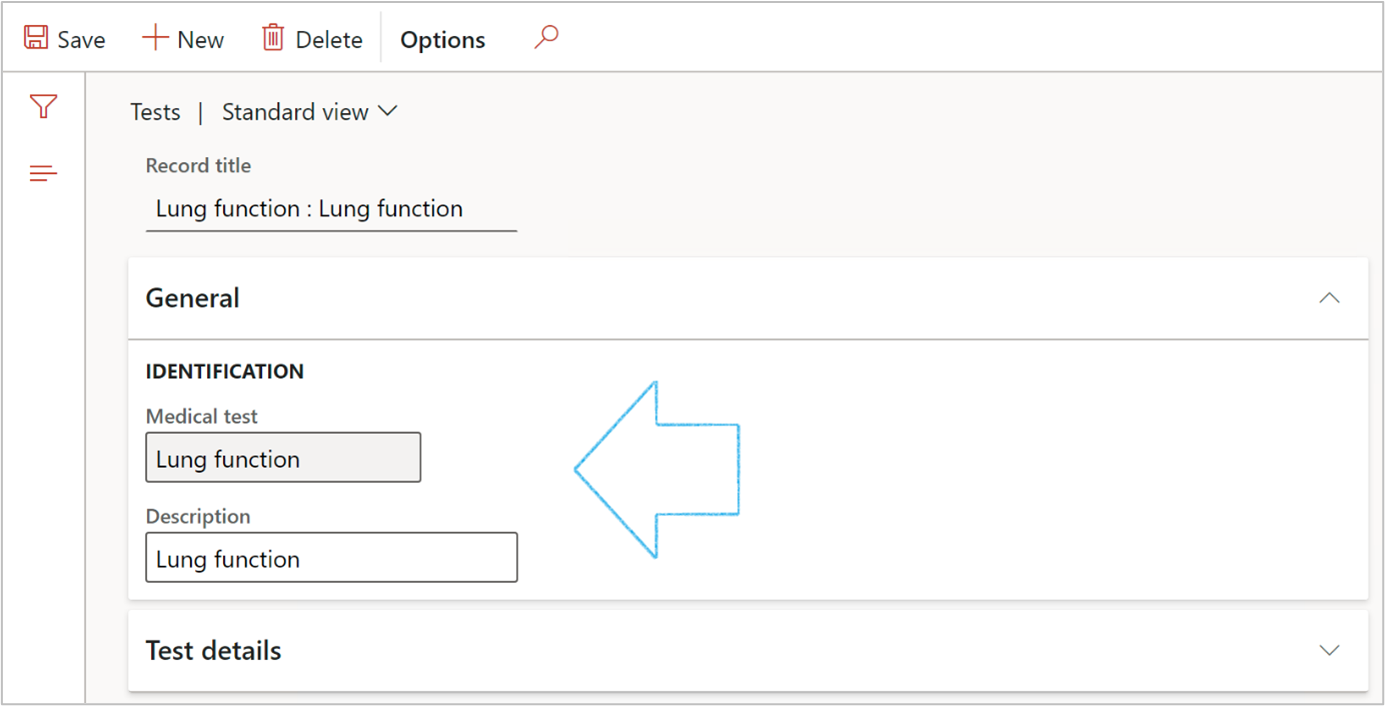

¶ Step 7: Setup Tests

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Tests

- On the Action pane, click on the New button

- In the Medical test field, enter the name of the test

- Enter a Description for the test

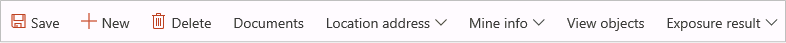

¶ Step 8: Setup Workplace/Location

Go to: Health, Safety and Environment > Locations

The button strip:

- New: To add a new location

- Delete: To delete a record

- Location layout: A schematic layout diagram can be attached to this location

- Location address: Use this button to maintain the location address

- Mine info: The mining info needed for the DMR reports

- View objects: View objects linked to this location – Not used in HEG

- Exposure results: This is where exposure results can be accessed

- Expand the General Fast tab and enter the following details:

- Location ID: A unique identification ID for the location

- Description: A description for this location

- Parent: The parent location, the top node of the hierarchy will not have a parent

- Select the relevant Site from the dropdown list

- Location (Work centre): The work centre linked to this location

- Indicate whether this is an Active location

- Selectable: An indicator to mark this record as selectable on defining an incident (see tree view)

- Pollutant group: The pollutant group linked to this location

- The CSA Reporting field will display whether this location is a confined space/asbestos is present

The CSA Reporting is setup on the Hazard under the General Fast tab

- Indicate whether this Location is appropriately Labelled for the present hazards

- Indicate whether the space is Enclosed

These locations are also used in other HSE sub-modules

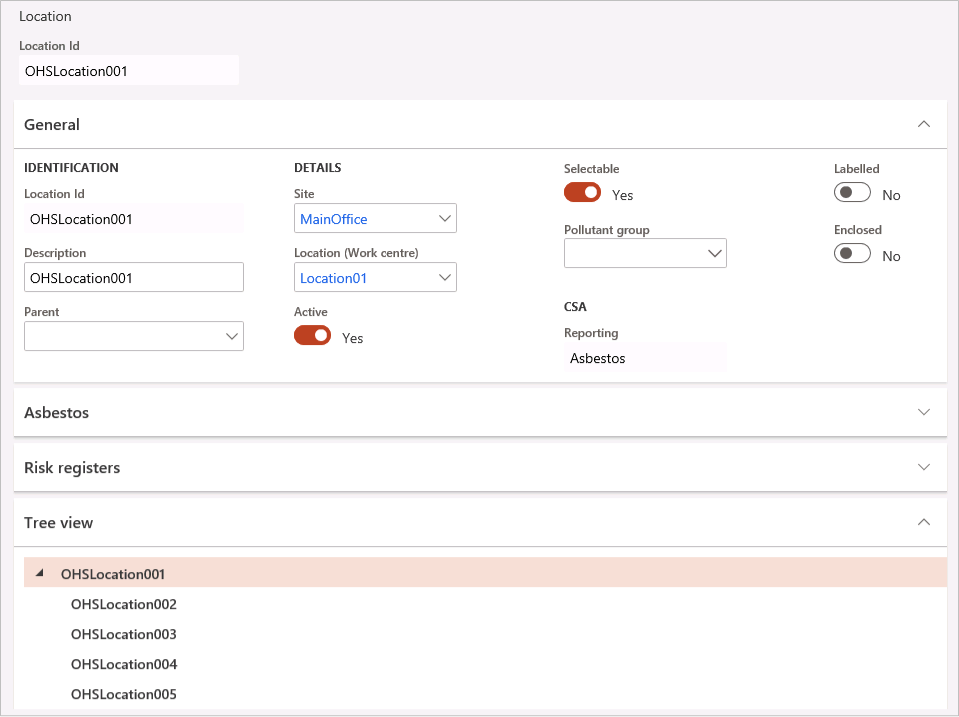

¶ Step 9: Setup Mine info

The mining info is needed for the DMR reports. Enter all details as required on the DME reports.

Go to: Health, Safety and Environment > Locations

- Click on the Mine info button

- Under the Mine field group, enter the following:

- Mine name: The mine name

- Address: The mine address

- Under the Mining info field group, enter the following:

- DME mine code: The DME mine code

- DME sub mine code field, enter the DME sub mine code

- Main commodity: The main commodity detail

- Code: The main commodity code

- Commodities: Commodities detail

- Control group: Control group detail

- Production: Production detail

- Process: Process detail

- Under the Manager field group, enter the following:

- Manager: Manager detail

- Contact details (Telephone, Fax, E-mail)

- Under the Engaged occupational hygienist field group, enter the following:

- Occupational hygienist: Occupational hygienist name

- Full time/Part time: Select if the Occupational hygienist’s employment

- Contact details (Telephone, Fax)

- Directorate: Occupational hygienist Directorate

- MEC Certificate No and/or SAIOH Registration No: Occupational hygienist MEC Certificate No and/or SAIOH Registration No

- Contact details (Telephone, E-mail)

- Click OK

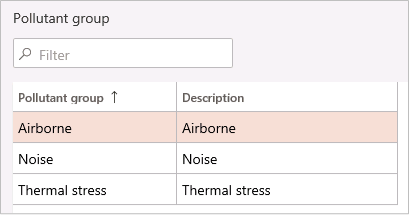

¶ Step 10: Setup Pollutant group

Pollutant groups are used to manage pollutants by dividing the pollutants into groups.

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Pollutant group

- To add a pollutant, click New

- In the Pollutant Group field, type a unique identification ID for the pollutant group

- In the Description field, type a short description for this pollutant group

- Click Save

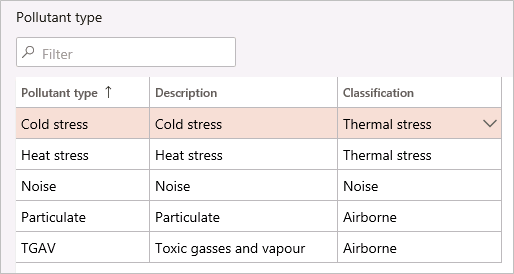

¶ Step 11: Setup Pollutant type

A pollutant type is a dividing of a Pollutant group. For example “Cold stress” and “Heat stress” are both of type “Thermal stress”.

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Pollutant type

- To add a pollutant type, click New

- In the Pollutant type field, enter a unique identification ID for the Pollutant type

- In the Description field, enter a description or name for this Pollutant type

- In the Classification field, select the classification from the dropdown list

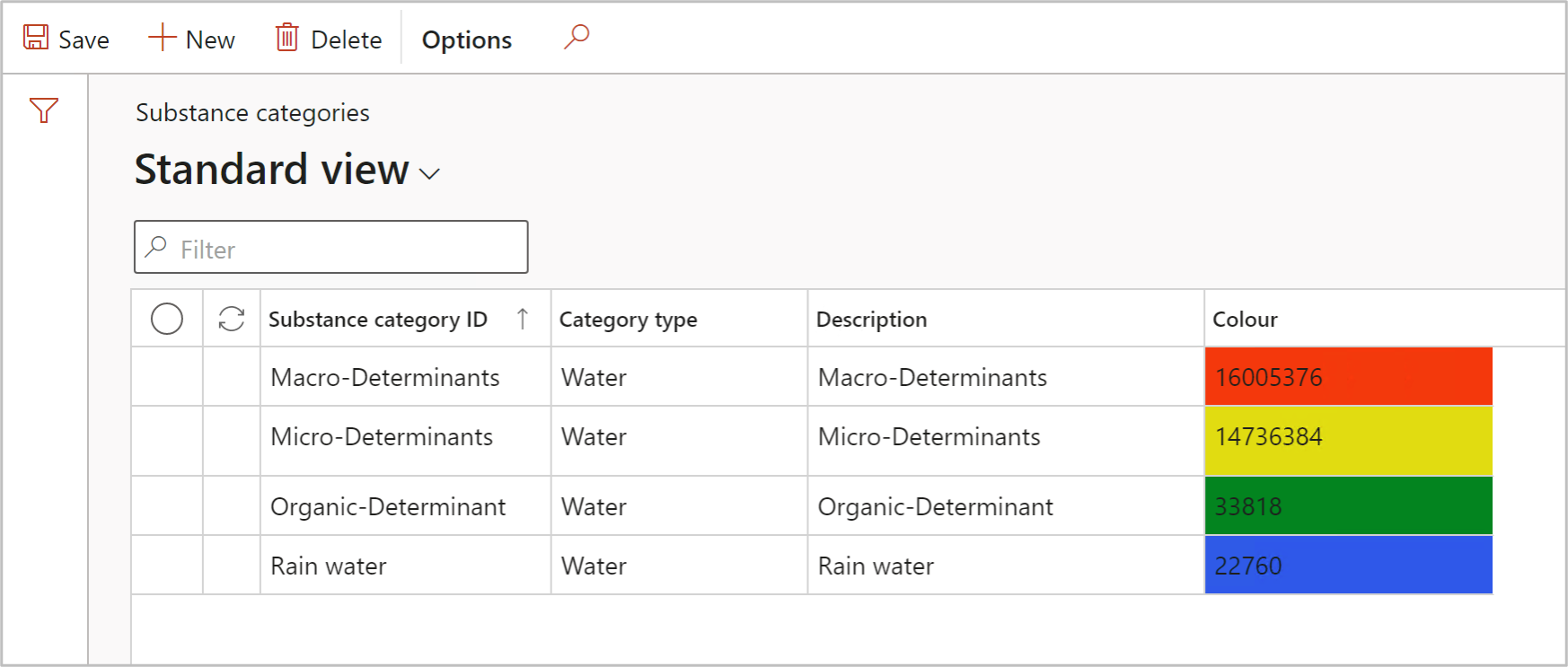

¶ Step 12: Setup Substance categories

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Substance categories

- In the Action pane, click on the New button

- Enter a unique Substance category ID

- Select the relevant Category type from the dropdown list

- Enter a brief Description for the substance category

- Select the relevant Colour for the substance category

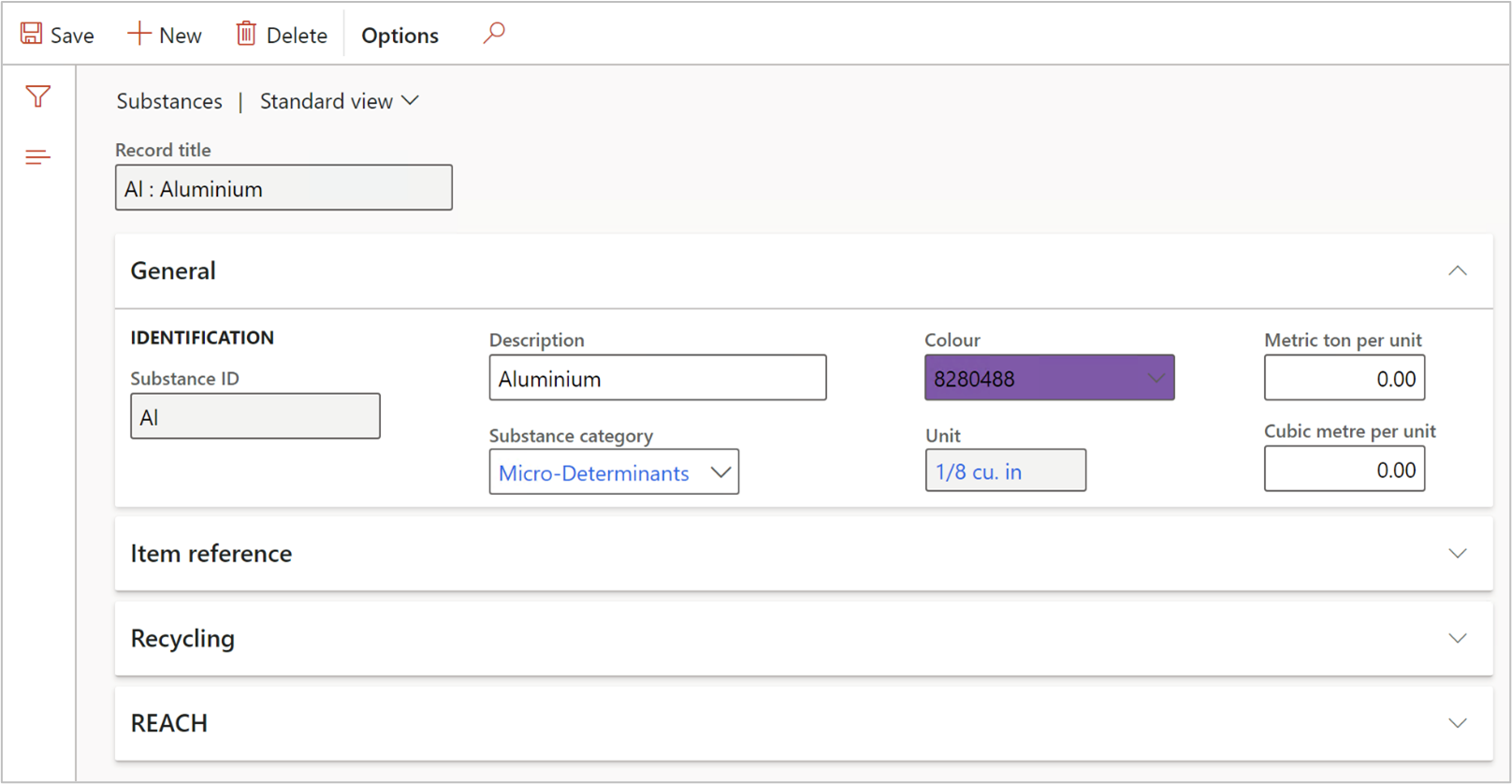

¶ Step 13: Setup Substances

This form is used to create a list of substances that need to be tracked by companies. The list can be used for tracking and reporting.

This is where the setup is done for the pollutant/substances code as described by the DMR in the SAMOHP codebook.

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Substances

- To add a substance, click New

- In the Substance ID field, enter the name of the substance ID (The DME substance code)

- In the Description field, enter a brief description of the substance

- Select the relevant Substance category from the dropdown list

- In the Units field, select the unit of measure for the substance

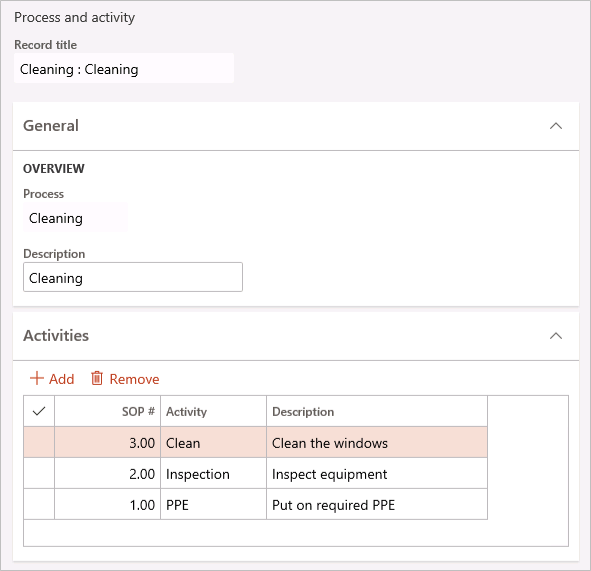

¶ Step 14: Setup Process and activity

This form is used by an organization to maintain processes and activities involved while executing operational work. The Activity area code list is as it is set in the SANOHP codebook

Go to: Health, Safety and Environment > Setup > Process and activity

- Under the General Fast tab, fill in the following:

- Process: A unique identification ID for the process

- Description: Description or name for this process

- Expand the Activities Fast tab

- Click Add

- In the Activity ID field, enter a unique identification ID for the activity

- In the Description field, enter a description or name for this activity

The SOP# field is not used in Industrial hygiene

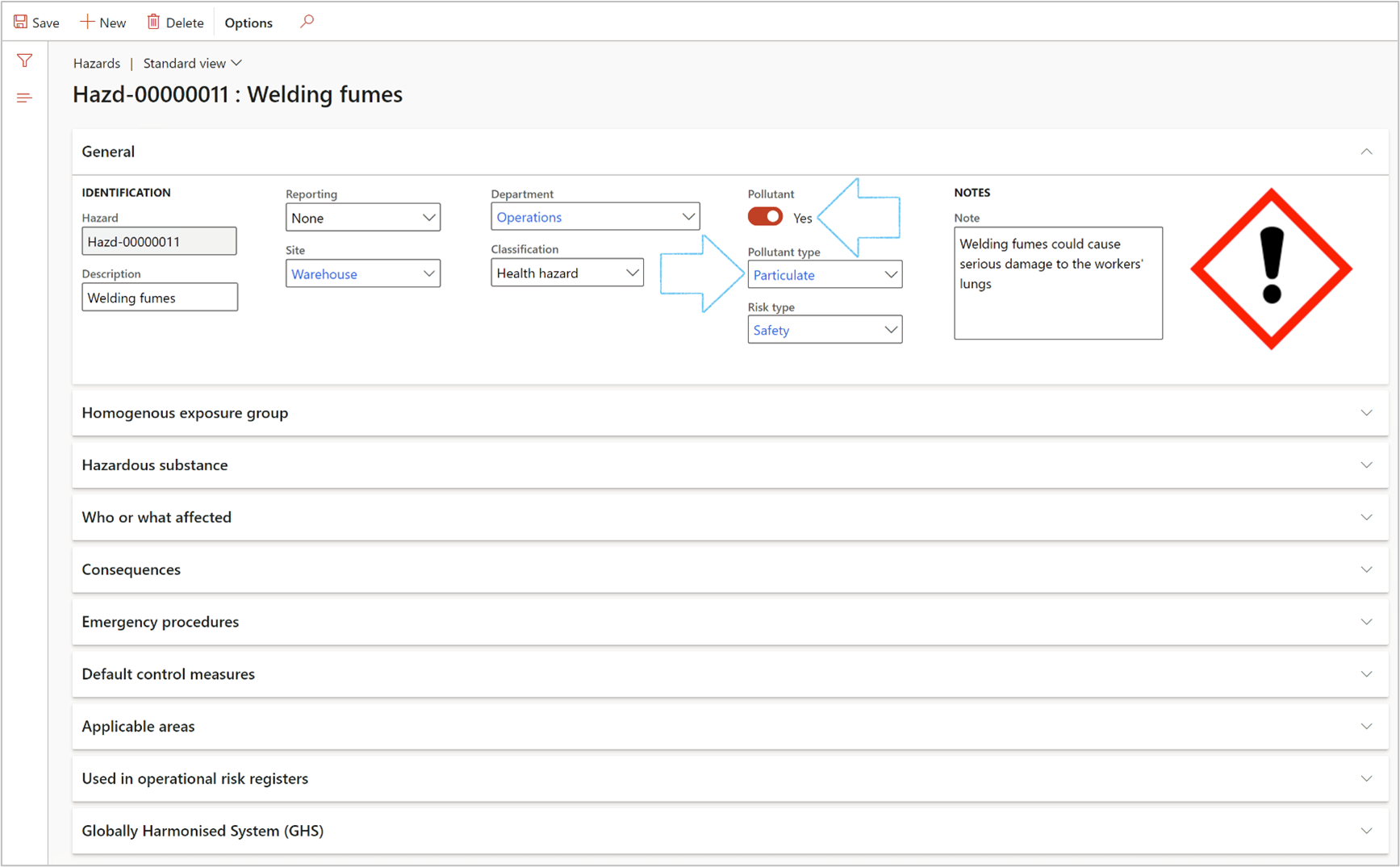

¶ Step 15: Setup Pollutants

A pollutant is a substance or energy introduced into the environment that has undesired effects, or adversely affects the usefulness of a resource. A pollutant may cause long- or short-term damage by changing the growth rate of plant or animal species, or by interfering with human amenities, comfort, health, or property values.

Go to: Health, Safety and Environment > Industrial hygiene > Pollutants

- Under the General Fast tab, enter the following:

- Enter a brief Description or name for this hazard

- Select the Site that this hazard is linked to

- Select the Department that this hazard is linked to

- Select the relevant hazard Classification from the dropdown list

- Indicate whether this hazard is a Pollutant

- Select the relevant Pollutant type from the dropdown list

- Enter additional information about this hazard in the Note box provided

- Expand the Homogeneous exposure group Fast tab

- Under the Exposure limits Field group, click on the Add button

- Sub-type: Select all the readings used in the calculation of the band

- Short term value: Indicates the short term OEL (occupational exposure limit) meaning a limit value set by the Minister for a stress factor in the workplace, as revised from time to time by notice in the Government Gazette

- Long term value: Indicates the long term OEL (occupational exposure limit) meaning a limit value set by the Minister for a stress factor in the workplace as revised from time to time by notice in the Government Gazette

- Unit: Indicates the unit of measure that will be used for this reading

- Select the relevant Pollutant group linked to the hazard

- Under the Is pollutant Field group:

- Indicate whether the pollutant is Significant

- Indicate whether this pollutant is Addictive

- Indicate whether this pollutant is going to be measured directly against a worker

- Indicate whether the Inverted scale for the exposure calculation done on the HEG e.g., for Cold stress, should be used for this pollutant

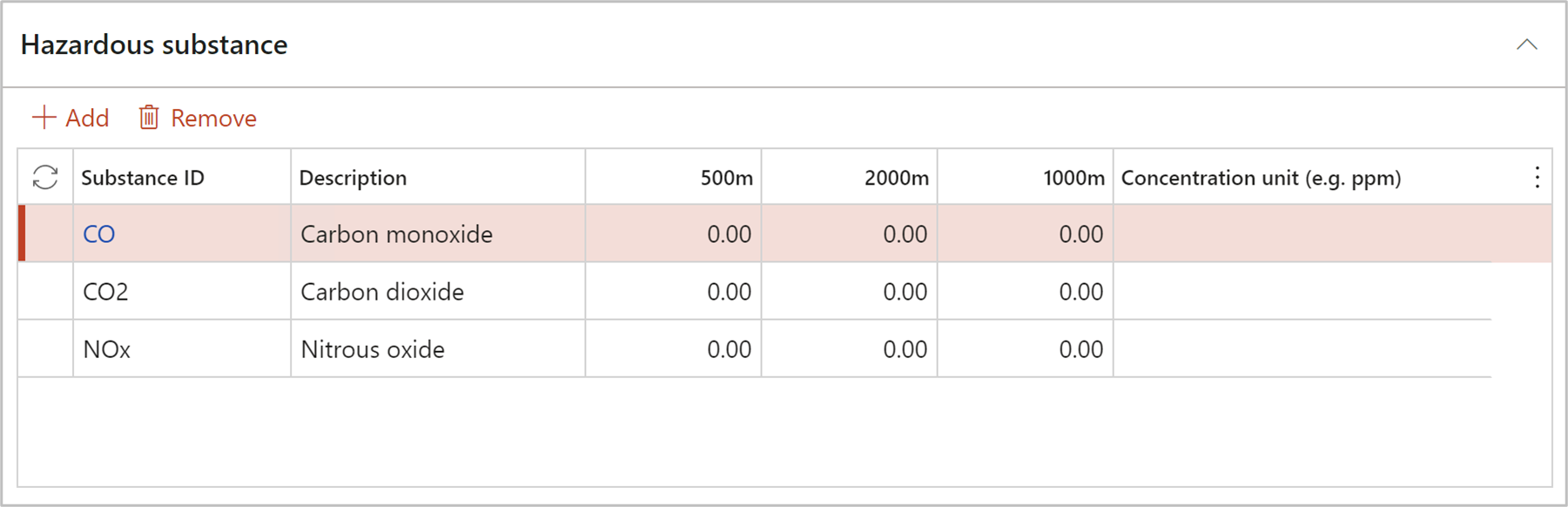

- Expand the Hazardous substance Fast tab

- Substance: Substance linked to this hazard; this will be used for the reporting as set in the SANOHP codebook

- Description: The substance description

- Estimate the concentration of the pollutant in water, soil and/or air within a 500m radius of the epicentre of the incident

- Estimate the concentration of the pollutant in water, soil and/or air within a 2000m radius of the epicentre of the incident

- Estimate the concentration of the pollutant in water, soil and/or air within a 1000m radius of the epicentre of the incident

- Concentration unit: The unit of measure of this substance

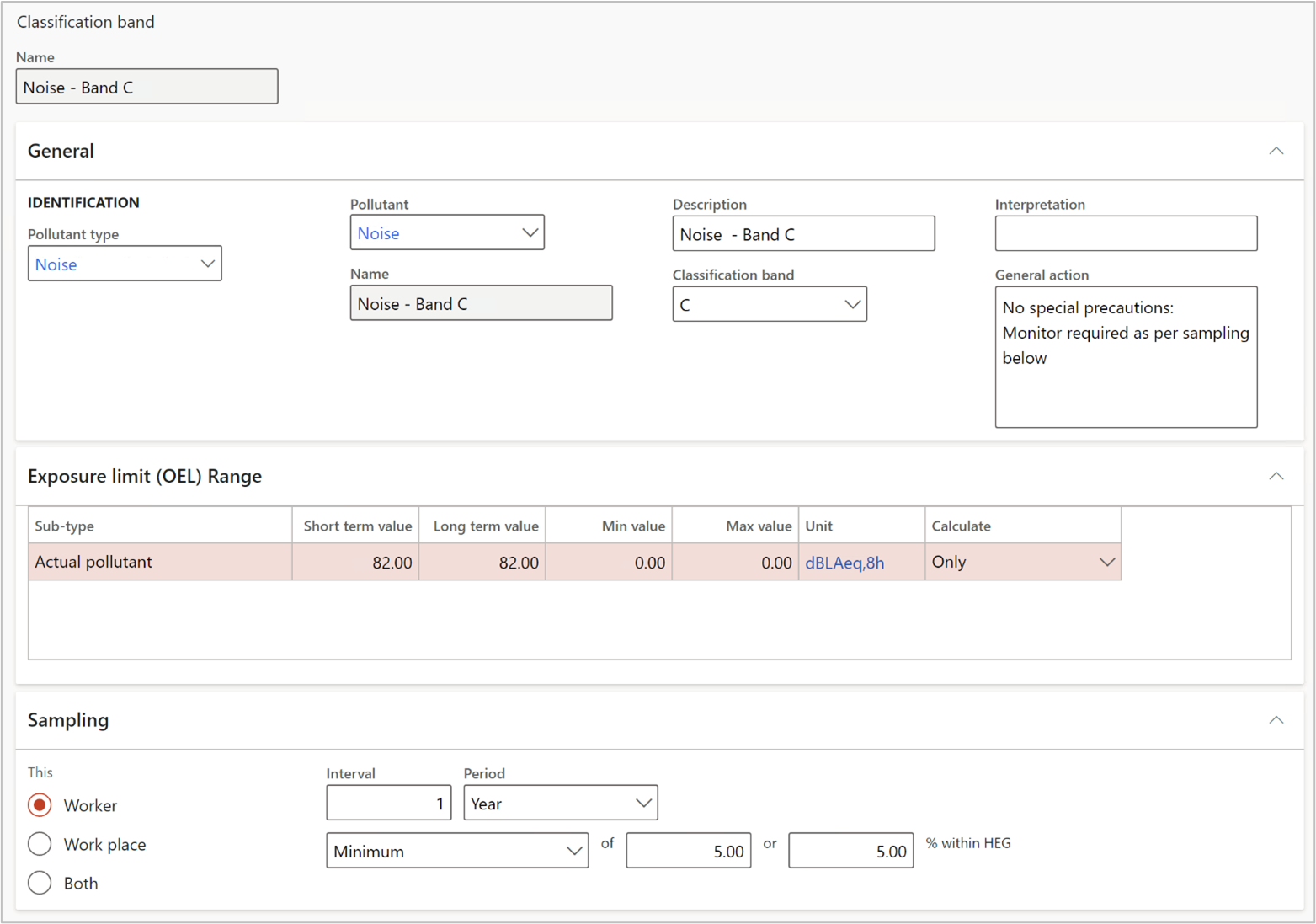

¶ Step 16: Setup Classification band

This form is used to maintain Classification bands. The setup of classification bands is used in the calculation of classification bands for a HEG, as well as the scheduling. (as set in the SANOHP codebook)

Go to: Health, Safety and Environment > Industrial hygiene > Setup for industrial hygiene > Classification band

- The General Fast tab: Identification information is captured

- The Exposure limit (OEL) Range Fast tab: The Classification band ranges, and formula are displayed

- The Sampling Fast tab: The sample frequency used when scheduling the HEG is selected

- Select whether the samples to be taken are static/personal/both

- Enter the interval value and select the period

- Select what you want to calculate: Minimum/maximum/quantity/percentage

Set the number of samples to create records for when running the schedule

OR

Set the percentage of workers to be used in the samples to create records for when running the schedule

¶ Daily use

Typical flows

|

|

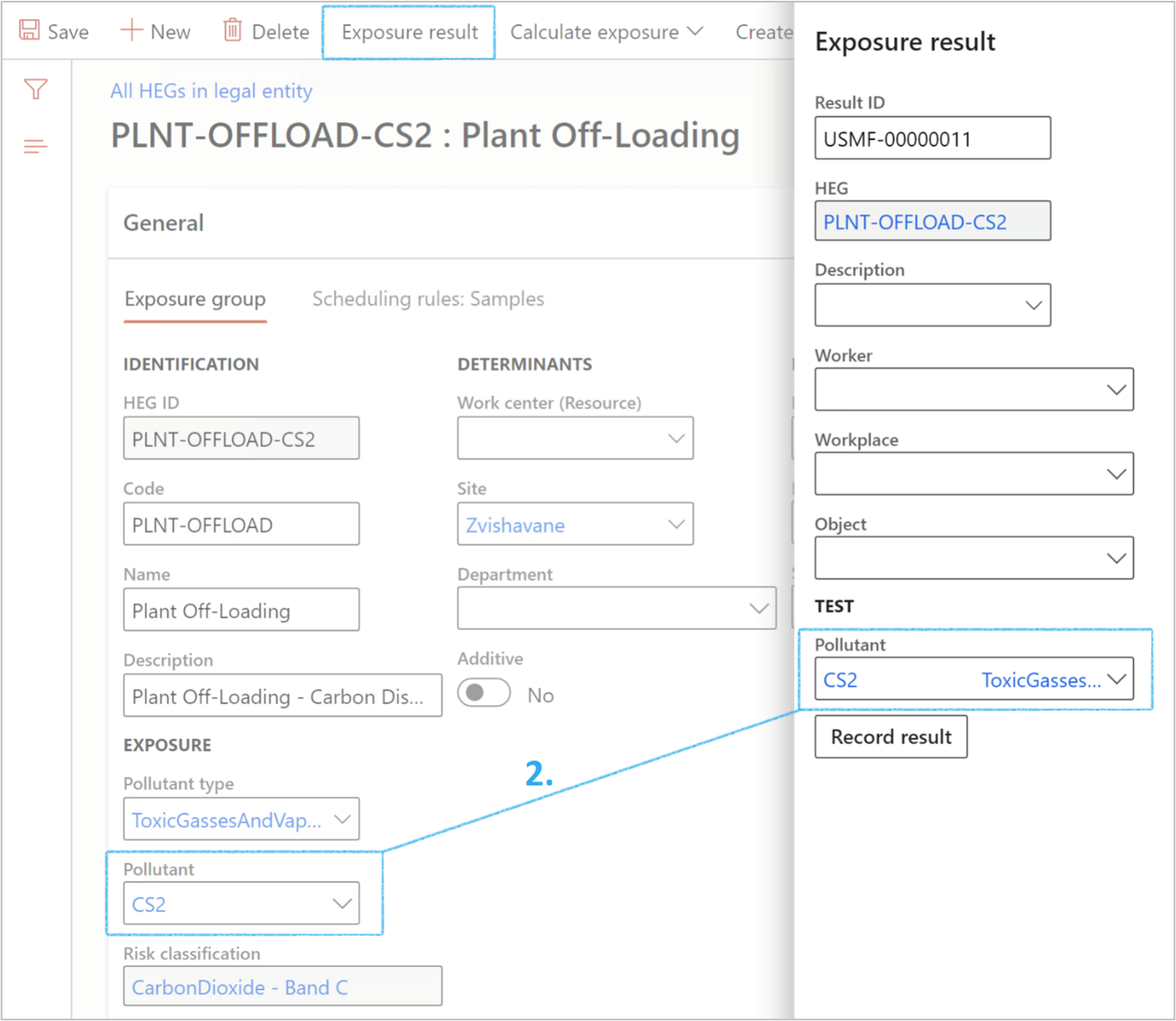

¶ Step 17: Create HEGs

Homogeneous exposure group is used to identify the people and workplaces that are exposed to similar agents and have a common exposure profile. This grouping enables enterprises to collect and examine exposure data for only a few people and a few workplaces and then to apply the findings and decisions to the rest of the group. HEGs help to minimize monitoring costs and to leverage exposure data to protect the health and safety of all people in the HEG.

Go to: Health, Safety and Environment > Industrial hygiene > All HEGs in legal entity

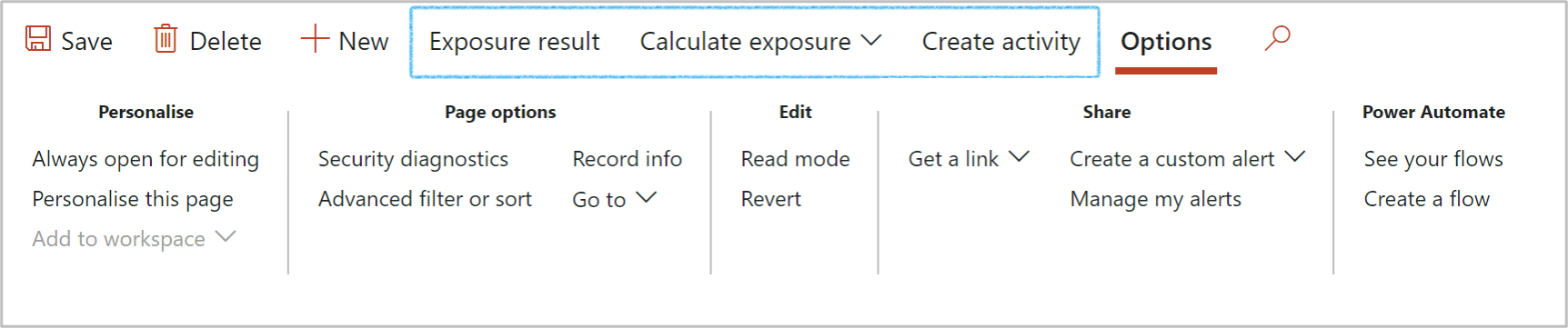

Functions of the buttons on the Action pane:

- Exposure result:

- For manually capturing an additional exposure result

- An Approved schedule is created

- Only workers belonging to the HEG, will be on the drop-down list

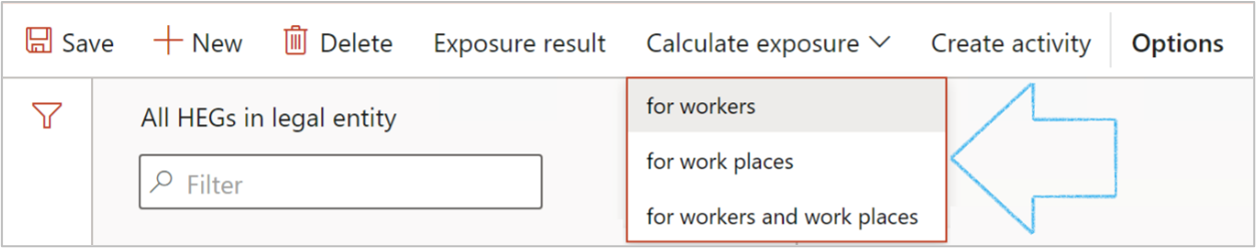

- Calculate exposure:

- Choose to calculate an exposure result for either workers, workplaces, or both

- This is usually done once a year

- Results are visible on the workers belonging to the HEG

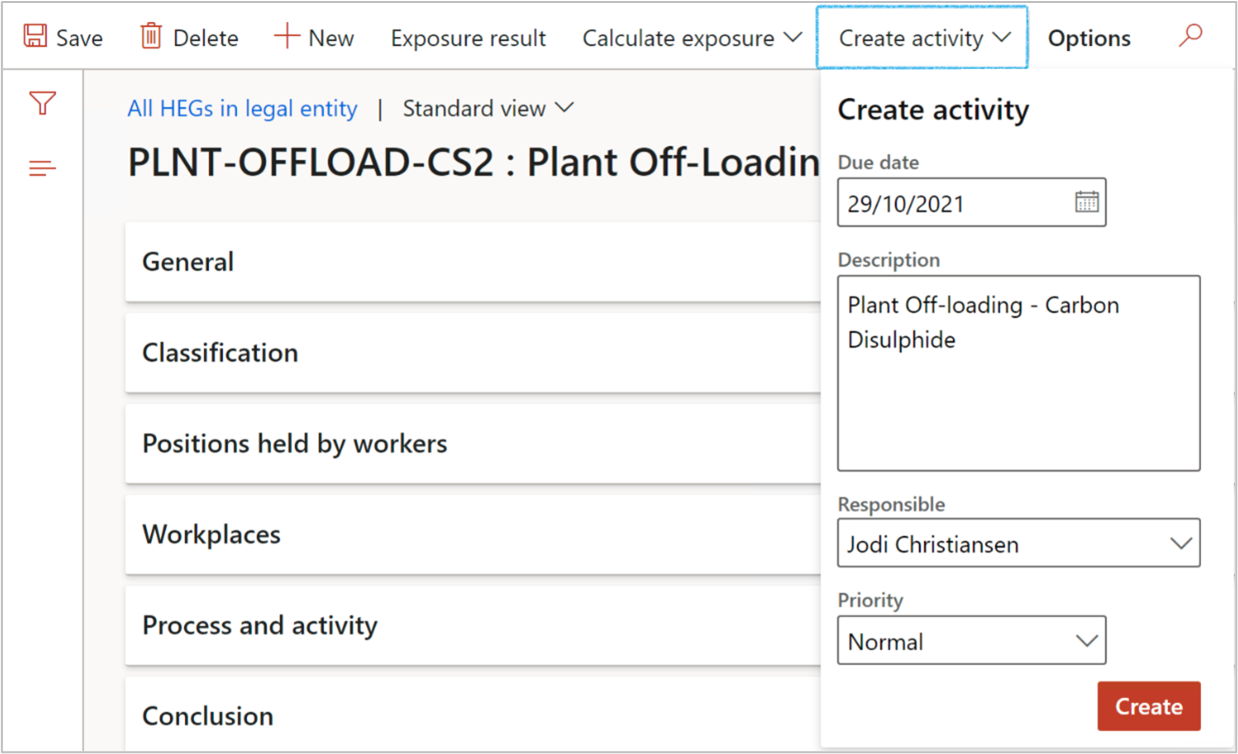

- Create activity:

- Send a reminder to someone by creating an activity. The activity will then show up on their activity list.

- The activity number is also displayed in the Related information pane

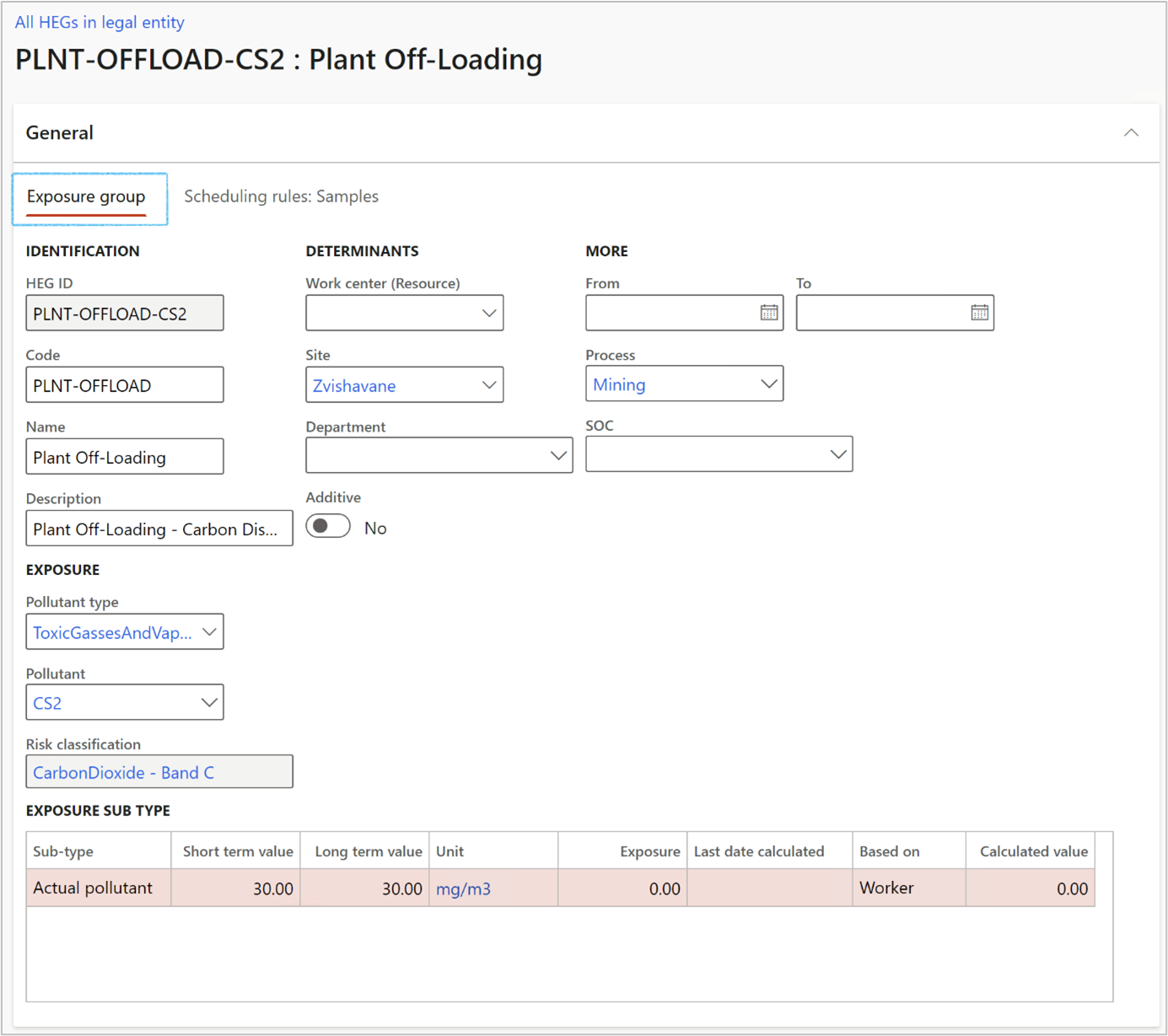

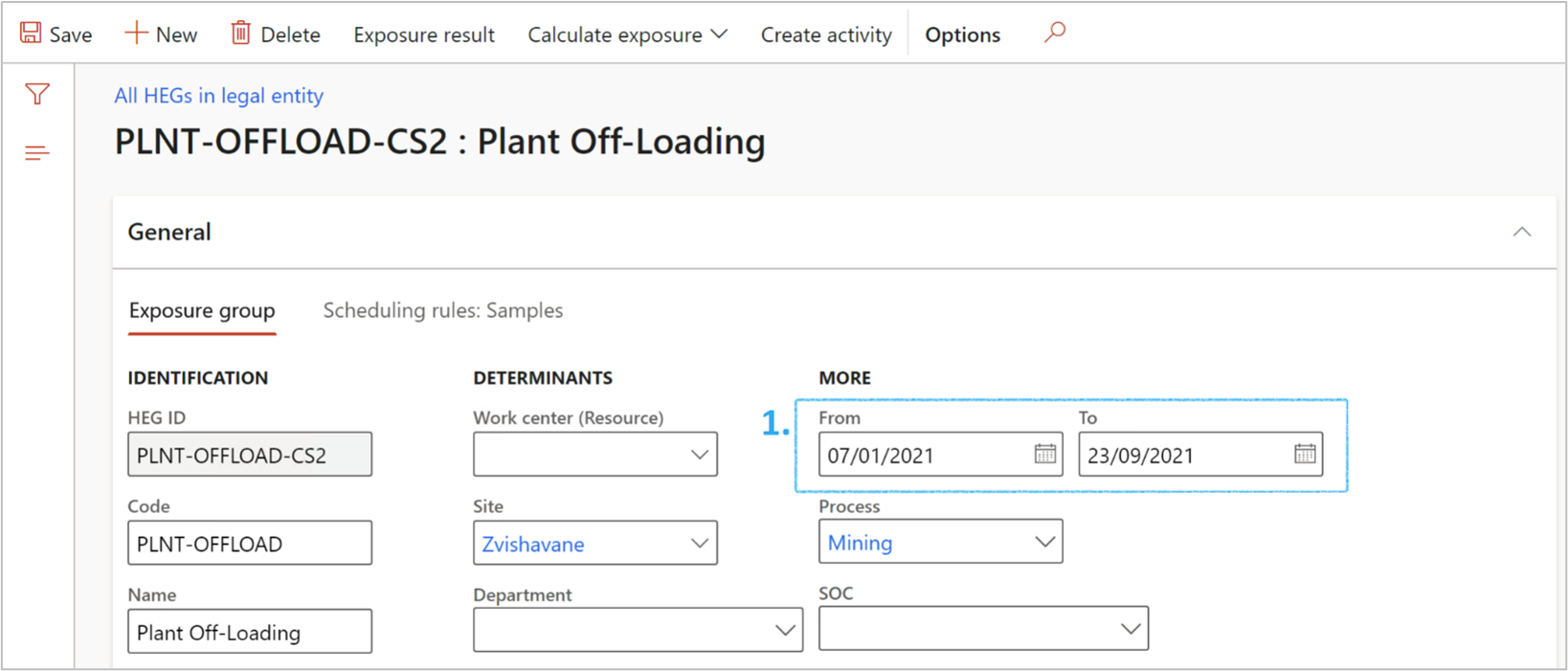

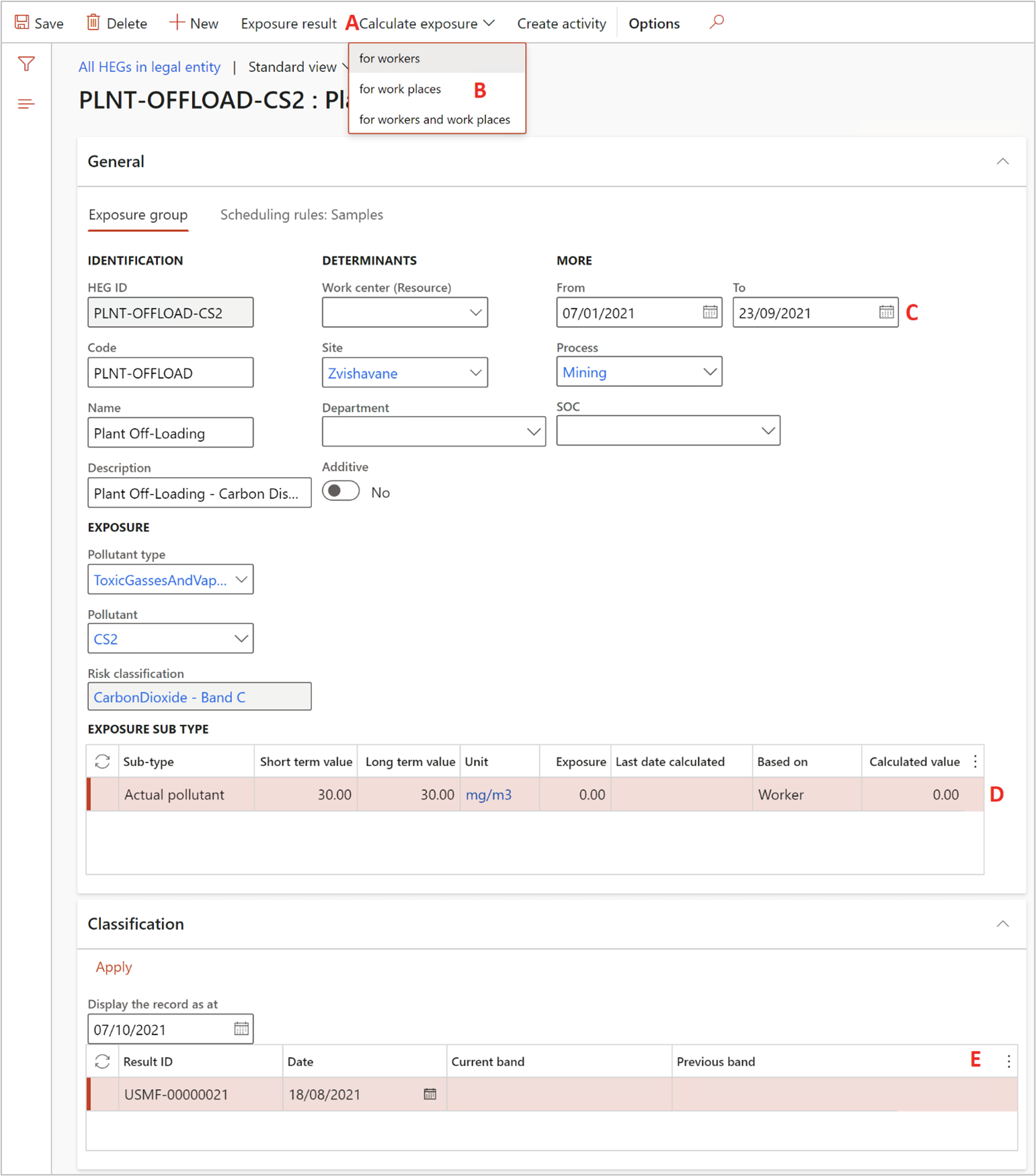

¶ Step 17.1: The General Fast tab (HEG meta data)

Under the Exposure group Index tab:

- Enter a unique HEG identification Code

- Enter the Name of the HEG

- Enter a brief Description of the HEG

- Select the relevant Pollutant type from the dropdown list

- Select the relevant Pollutant (Hazard) from the dropdown list

- Risk classification: Classification band (display only)

- Select the relevant Work centre (Resource) from the dropdown list

- Select the relevant Site from the dropdown list

- Select the relevant Department from the dropdown list

- Additive: Workers are frequently subjected to mixed exposures. This is when a significant pollutant that has an additive effect has been identified in an activity area

- Enter the From and To dates to use in calculation exposure

- Select the relevant Process form the dropdown list

- Select t eh relevant SOC (Standard Occupation Code) from the dropdown list

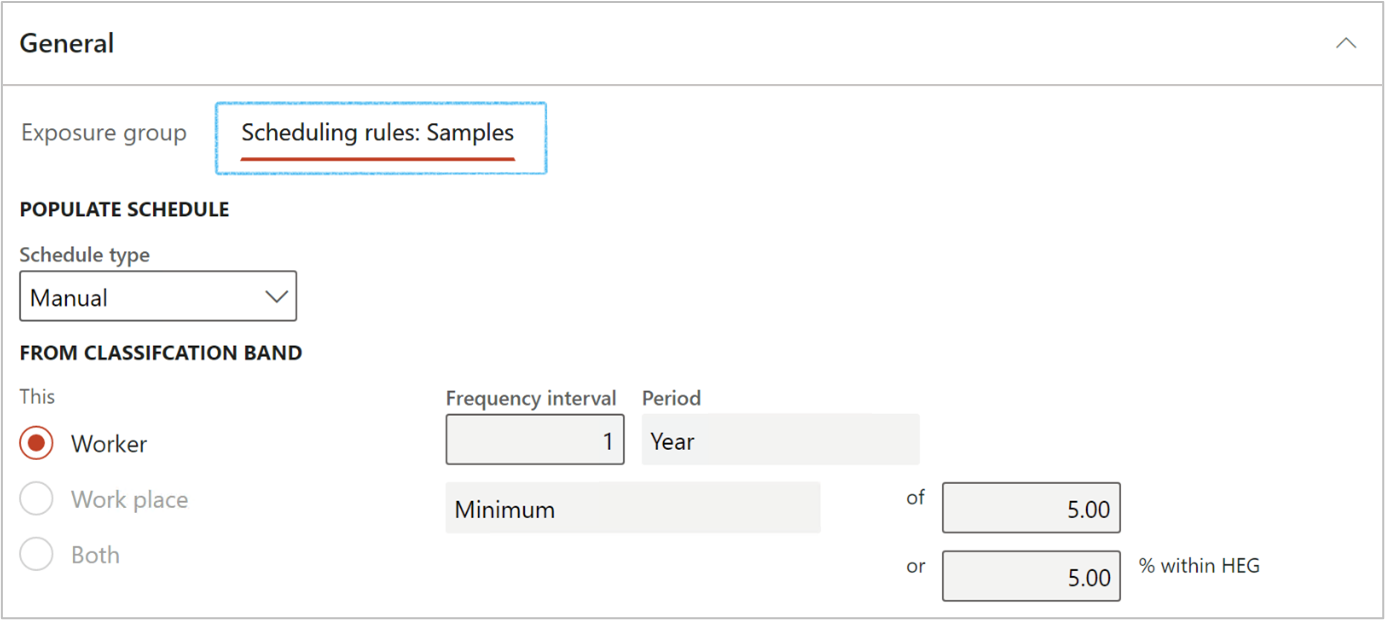

Under the Scheduling rules: Samples Index tab:

- Select whether the Schedule type is Manual/Calculated

Manual - This setting is to create a new schedule for a HEG without populating required tests (ResultID). One can therefore create new test records against this schedule as required.

Calculated - This setting creates a calculated schedule as per setup in Classification bands. Will create full schedule with a test(s) against each line schedule created for time periods specified in the setup.

- Under the Scheduling rules from Classification band Field group: Indicate whether samples are to be taken from the Worker/Workplace/Both

- The value in the Period field will be populated from the classification band, and used in scheduling

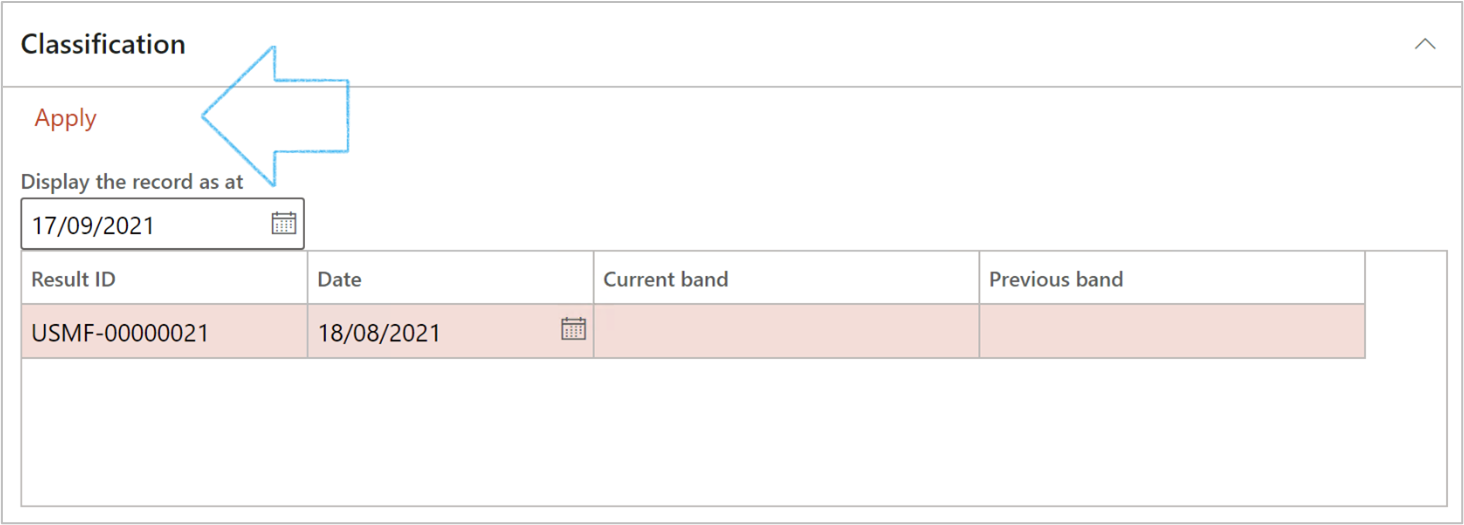

¶ Step 17.2: The Classification Fast tab

(Classification information history based on the bands that were created)

- Select the date for which the record should be displayed (The fields in the grid are displays only)

- Click on the Apply button to apply the date filter

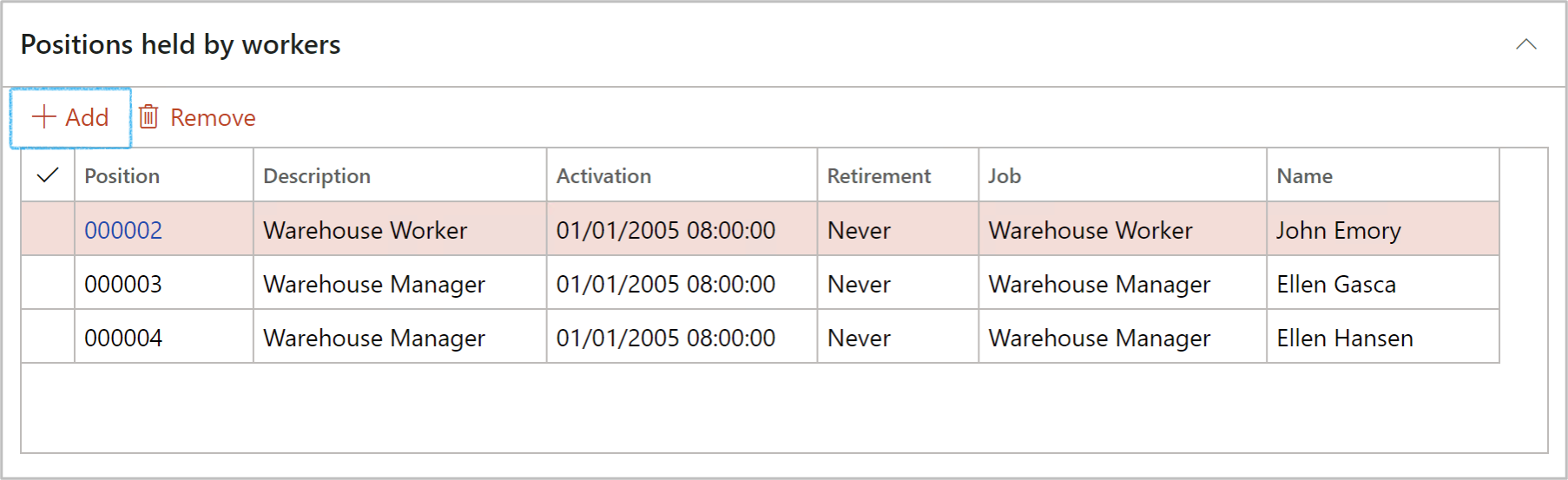

¶ Step 17.3: The Positions held by workers Fast tab

HEG groups of similar workers (via position)

- To add a new record, click on the Add button

- Select the Position that you want to add from the dropdown list

The other fields will be populated with the relevant data

Under this Fast tab, the user should list all positions exposed to this HEG. The worker assigned to this position must have an occupation code link to be able to produce the reports as set by the SAMOHP codebook

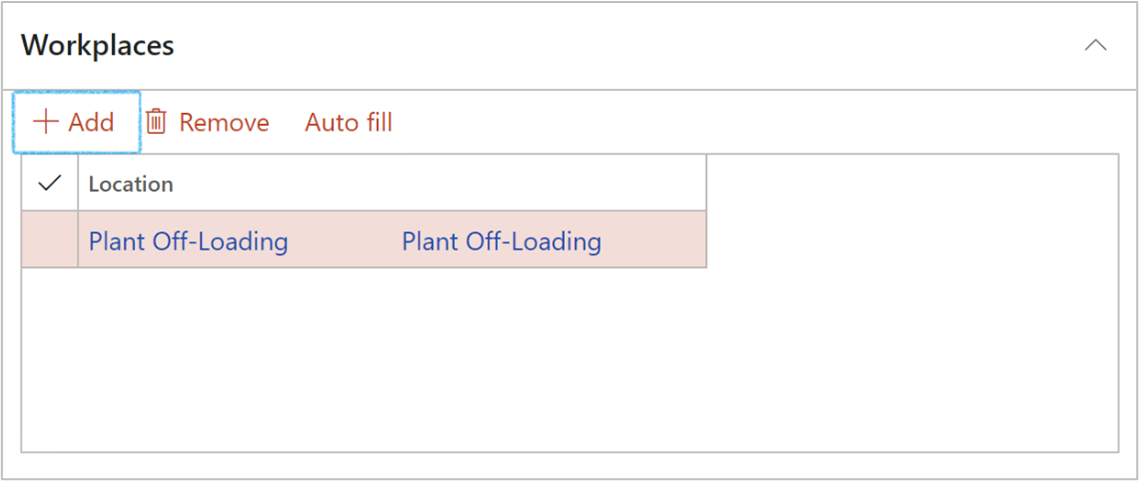

¶ Step 17.4: The Workplaces Fast tab

HEG groups of similar workplaces

- To add a new record, click on the Add button

- Select the relevant Location from the dropdown list

The reports to the DMR (Department of mines and minerals) SAMOHP codebook, requires that a user should link only one workplace to a HEG

¶ Step 17.5: The Process and activity Fast tab

Activities preformed at the location as set by the SAMOHP codebook

- To add a new record, click on the Add button

- Select the relevant Activity from the dropdown list

The reports to the DMR (Department of mines and minerals) SAMOHP codebook, the user should only link one activity to a HEG

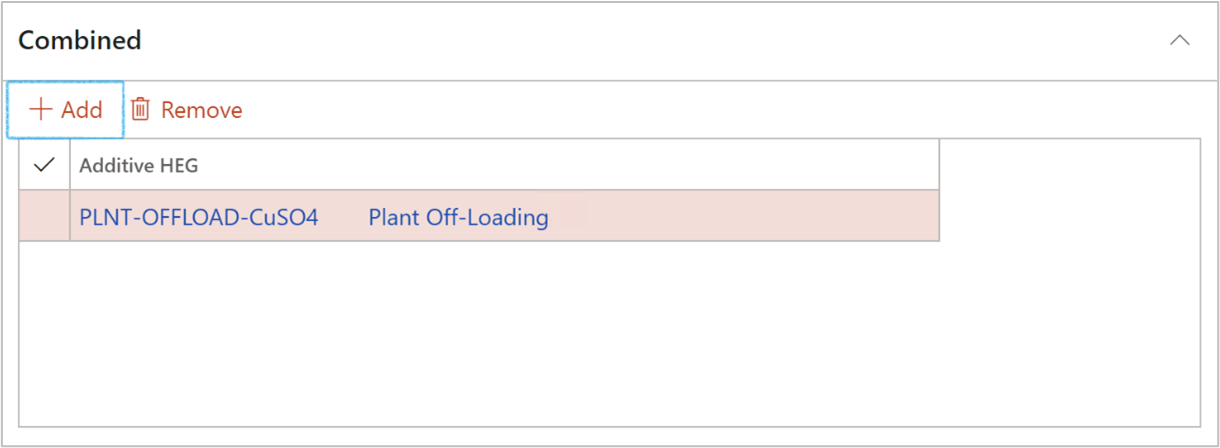

¶ Step 17.6: The Combined Fast tab

This is only when significant pollutants that have an additive effect have been identified under the General Fast tab

- To add a new record, click on the Add button

- Select the relevant Additive HEG from the dropdown list

This Fast tab is only available if this HEG is marked as an Additive

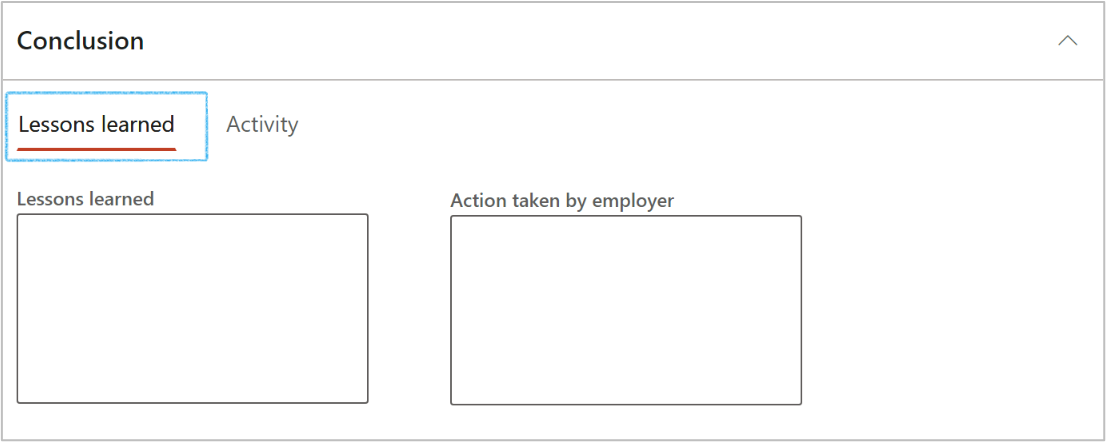

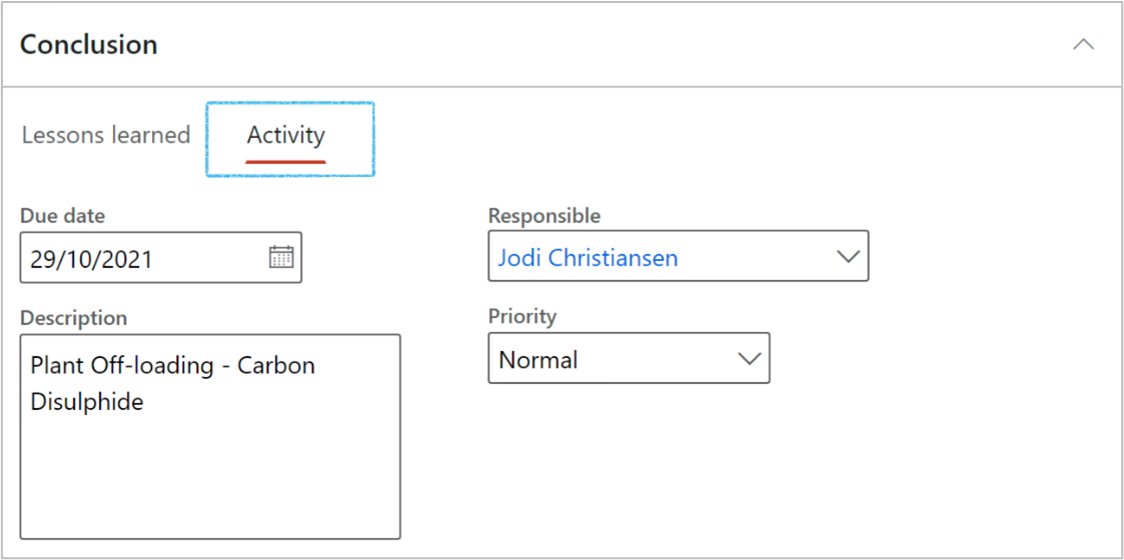

¶ Step 17.7: The Conclusion Fast tab

Under the Lessons learned Index tab:

- Enter Lessons learned in the box provided

- Enter Action taken by employer in the box provided

- On the Action pane, click on the Create activity button

- Complete the Create activity dialog with e following information:

- Select the Due date for the activity

- Enter a Description in the box provided

- Select the worker Responsible for the activity from the dropdown list

- Select the relevant Priority form the dropdown list

- Click on the Create button

- The information entered on the dialog will be visible under the Activity Index tab

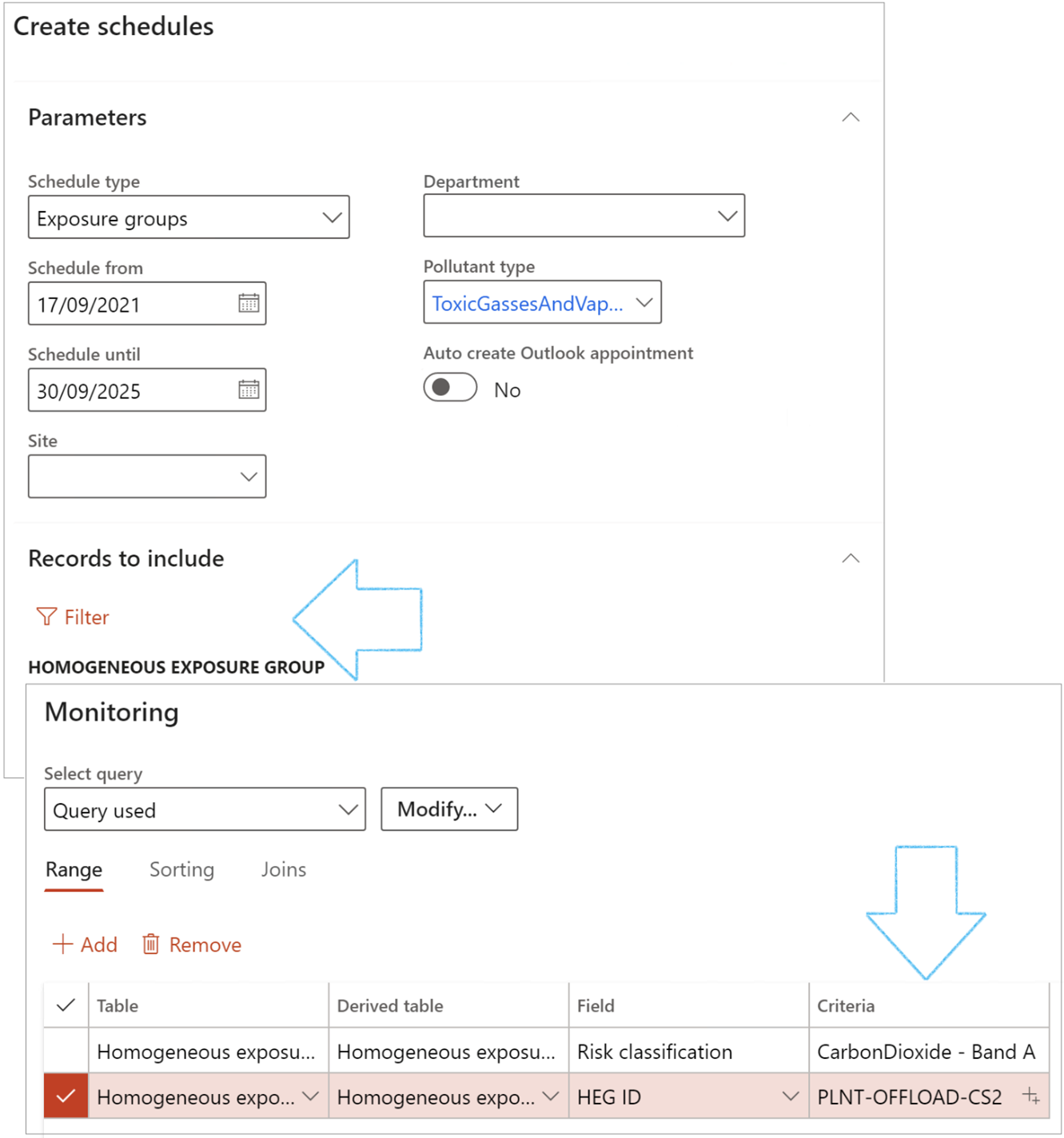

¶ Step 18: Create schedules

Go to: Health, Safety and Environment > Industrial hygiene > Schedules > All HEG sampling schedules

- On the Action pane, click on the New button

- Enter the following information on the Create schedules form:

- Schedule type: Select the schedule type (This scheduling is used for more modules in HSE, for this module we will select Exposure groups)

- Schedule from: Select the schedule from date

- Schedule until: Select the schedule until date

- Site: Select the site

- Department: Select the department

- Pollutant type: Select the pollutant type

- Auto create Outlook appointment: Mark this to automatically create an outlook appointment. (This is only relevant if the schedule type is meetings)

- Click on the Filter button

- Select the relevant values in the Criteria field

- Click OK

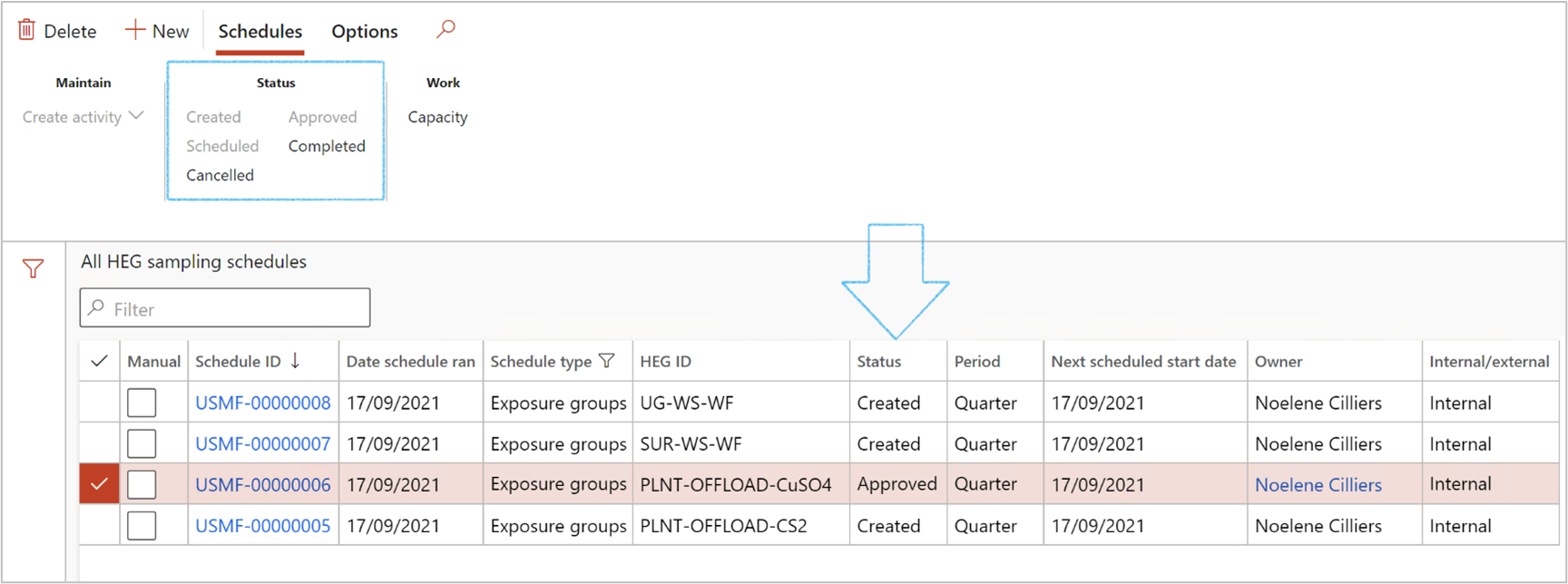

¶ Step 19: View all sampling schedules

Go to: Health, Safety and Environment > Industrial hygiene > Schedules > All HEG sampling schedules

Functions of the buttons on the Action pane:

- Delete: Only records with status Created can be deleted

- New: To create a new schedule

- In the Maintain group:

- Create activity: Activities that can be crated are Action/Appointment/Event/Task (Activities can only be created for records with status Created)

- In the Status group:

- Created: Change the status of the selected record to Created

- Scheduled: Change the status of the selected record to Scheduled

- Cancelled: Change the status of the selected record to Cancelled (If a record is marked as Cancelled, it cannot be changed to another status)

- Approved: Change the status of the selected record to Approved (Only records with status Approved can be edited)

- Completed: Change the status of the selected record to Completed (If a record is marked as Completed, it cannot be changed to another status)

Multiple scheduled HEG sampling records can be approved at the same time by selecting the relevant records and the clicking on the Approved button

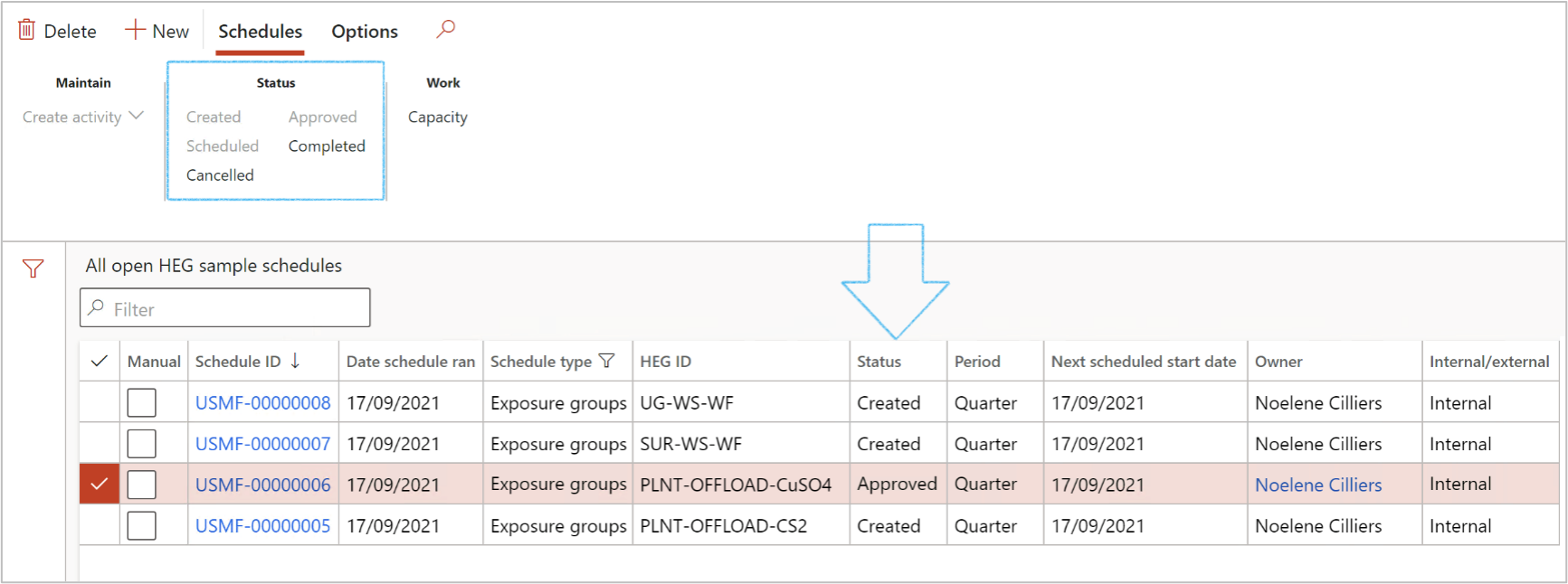

¶ Step 20: View all open sample schedules

This form shows all the open sample schedules with a status of not complete

Go to: Health, Safety and Environment > Industrial hygiene > Schedules > All open HEG sample schedules

The functions of the buttons on the Action pane are the same as on the All HEG sampling schedules form

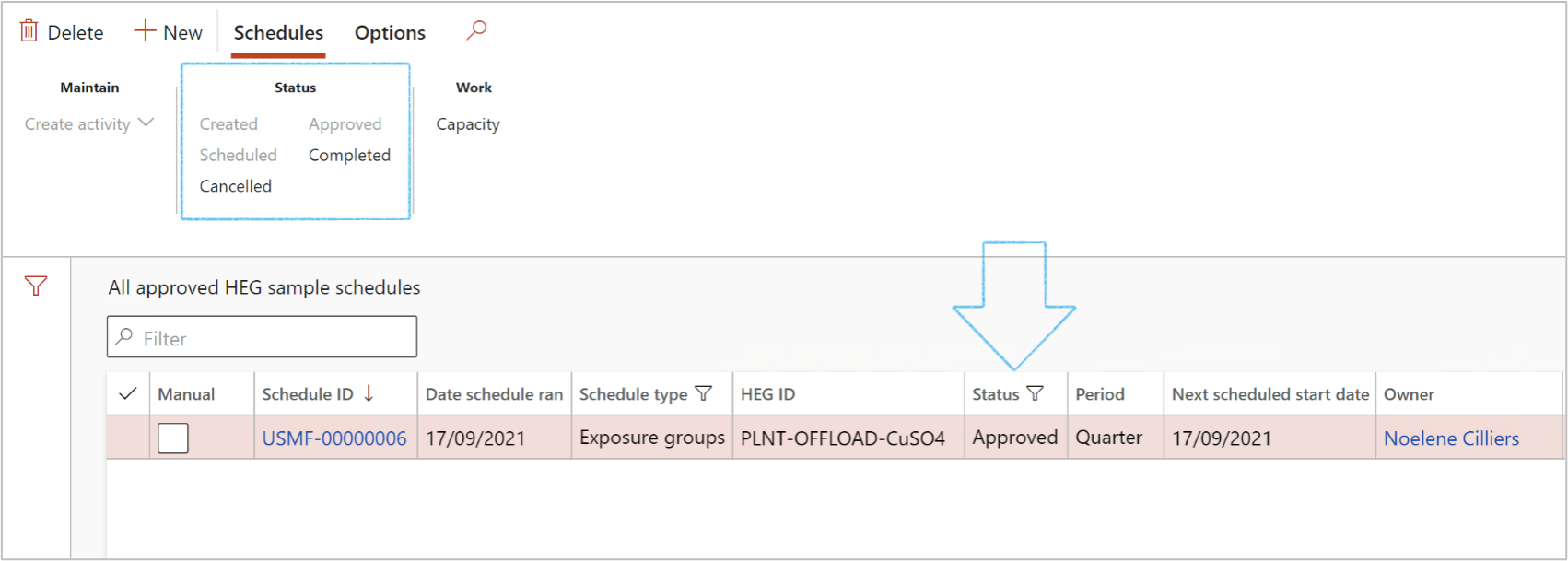

¶ Step 21: View all approved sample schedules

This form shows all the Approved sample schedules and can be used for the daily capturing of sample data

Go to: Health, Safety and Environment > Industrial hygiene > Schedules > All approved HEG sample schedules

- Click on the Schedule ID that you want to add results to

The functions of the buttons on the Action pane are the same as on the All HEG sampling schedules form

Schedule statuses:

| Created |

|

| Approved |

|

| Completed |

|

¶ Step 21.1: Functions of the buttons on the sample schedules

Functions of the buttons on the Action pane:

- New: Creates a new ad-hoc sample record. This record will be marked as an Additional record

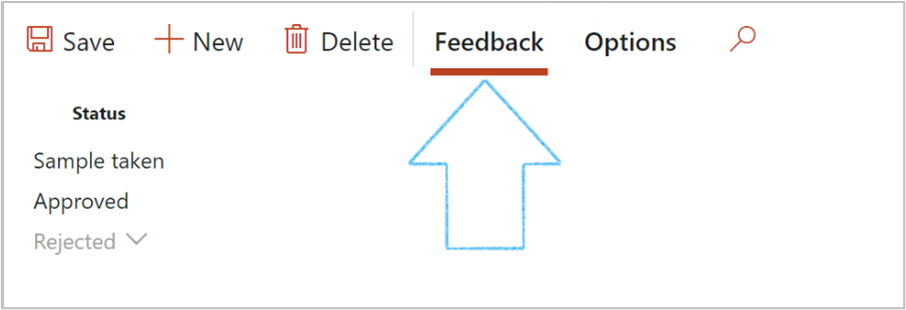

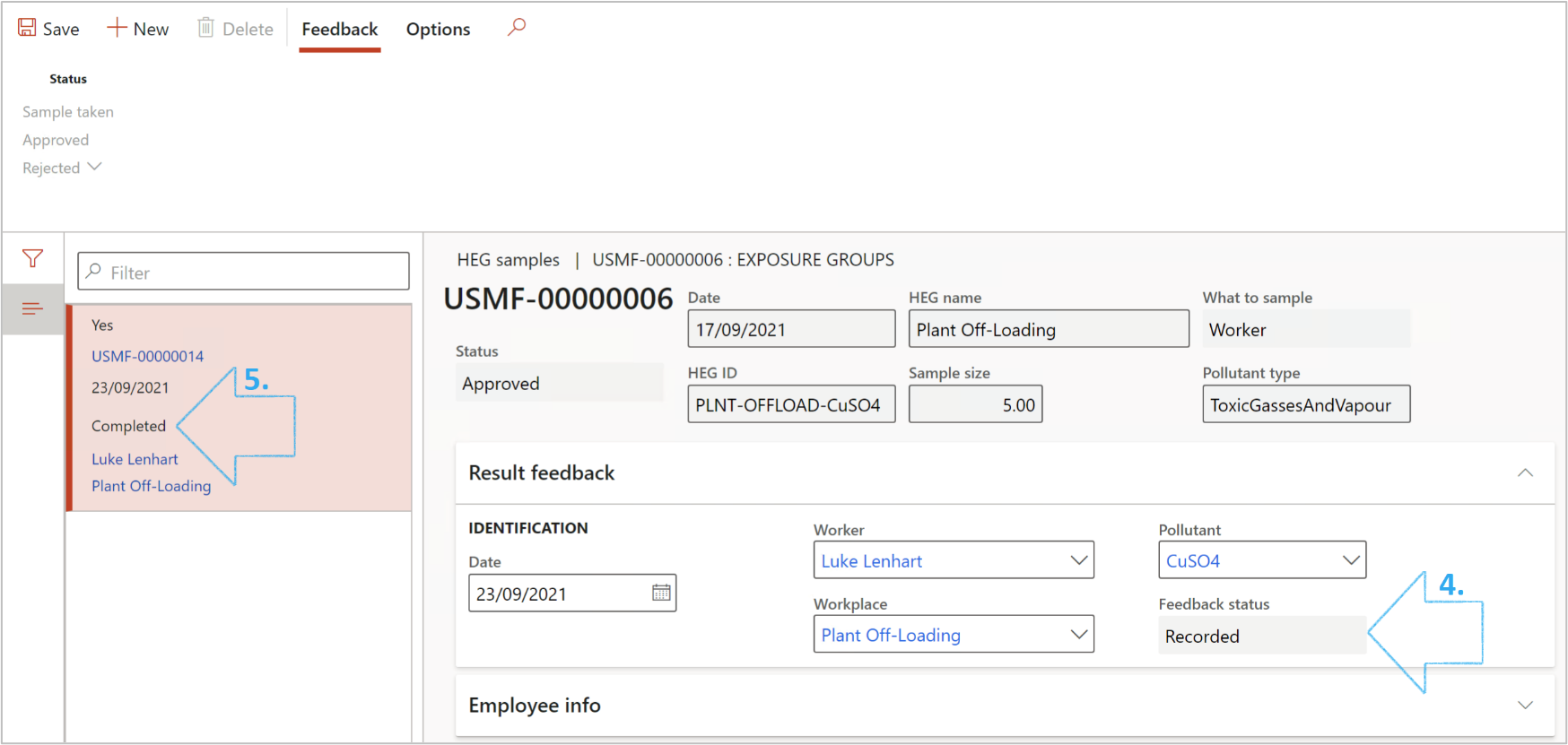

- Feedback tab:

- Sample taken: This will change the feedback status on the line to Sample taken

- Approved: This will change the feedback status on the line to Approved

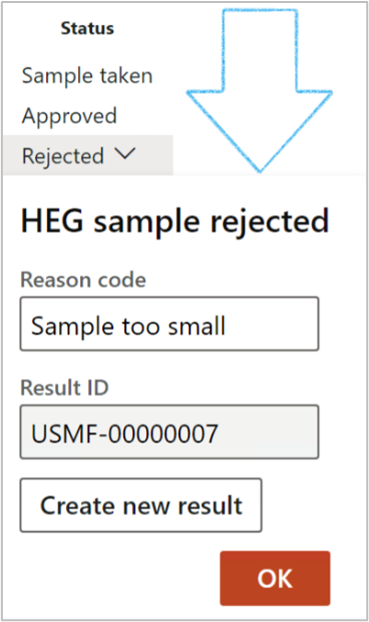

- Rejected: This will change the feedback status on the line to Rejected

If the sample is rejected, the following dialog will be displayed:

- Enter a reason why this sample is rejected

- Click O; to change the feedback status on the line to Rejected

- OR

- Click Create new result to change the feedback status on the line to Rejected and create a new sampling record. This record will be marked as an Additional record

- Record result: Changes the feedback status on the line to Recorded

Records with status Recorded cannot be changed

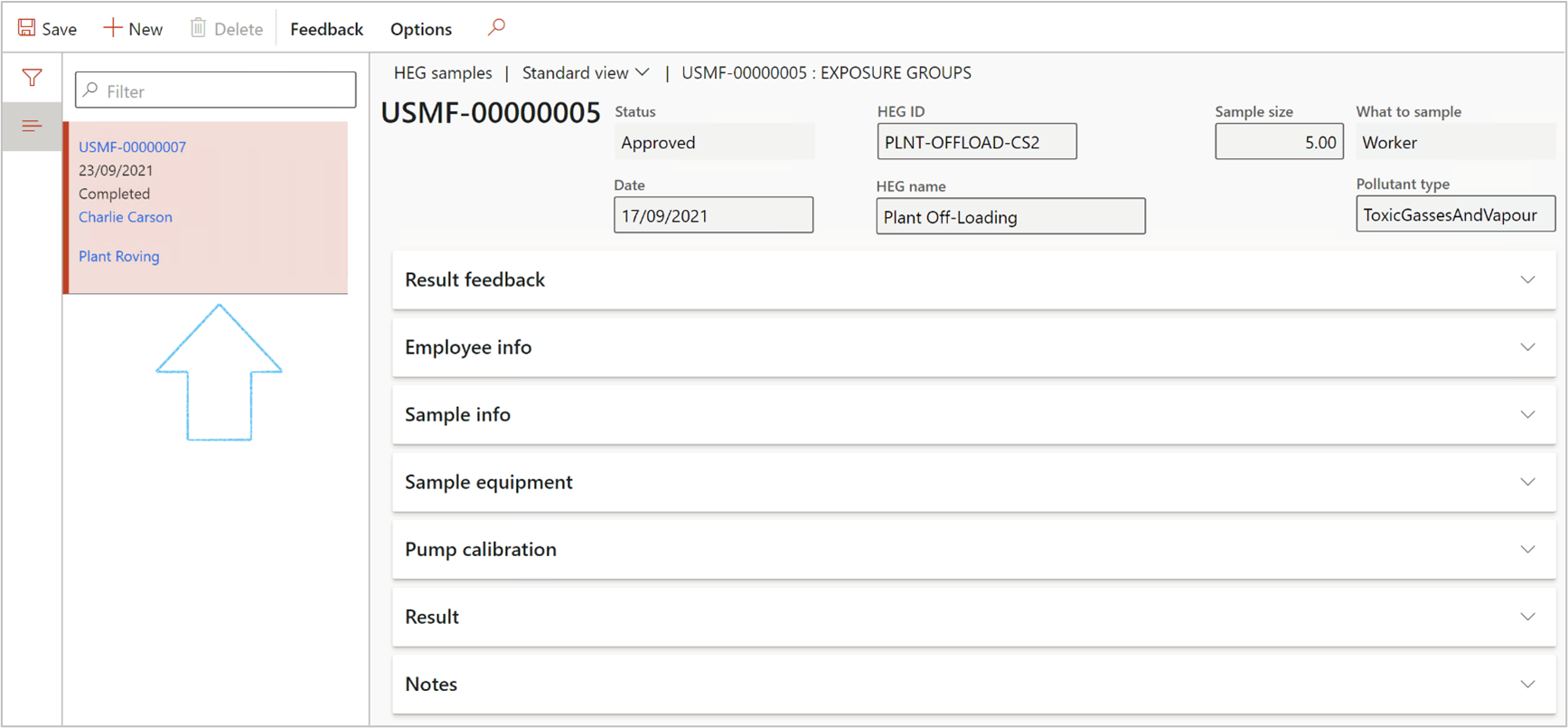

¶ Step 21.2: The “cards” on the left-hand side

- Results Id: A unique Id created by the system

- Date: The sample date created by the system

- Status: Status of the test result. This is changed from Created to Completed once the Record result button is clicked. This status must be Completed for the results to be used in calculations

- Worker: Select the worker involved with the sample

OR

- Workplace: Select the workplace where the sample was taken

If What to sample is Worker, then the worker field is mandatory

If What to sample is Workplace, then the workplace field is mandatory

¶ Step 21.3: The Fast tabs

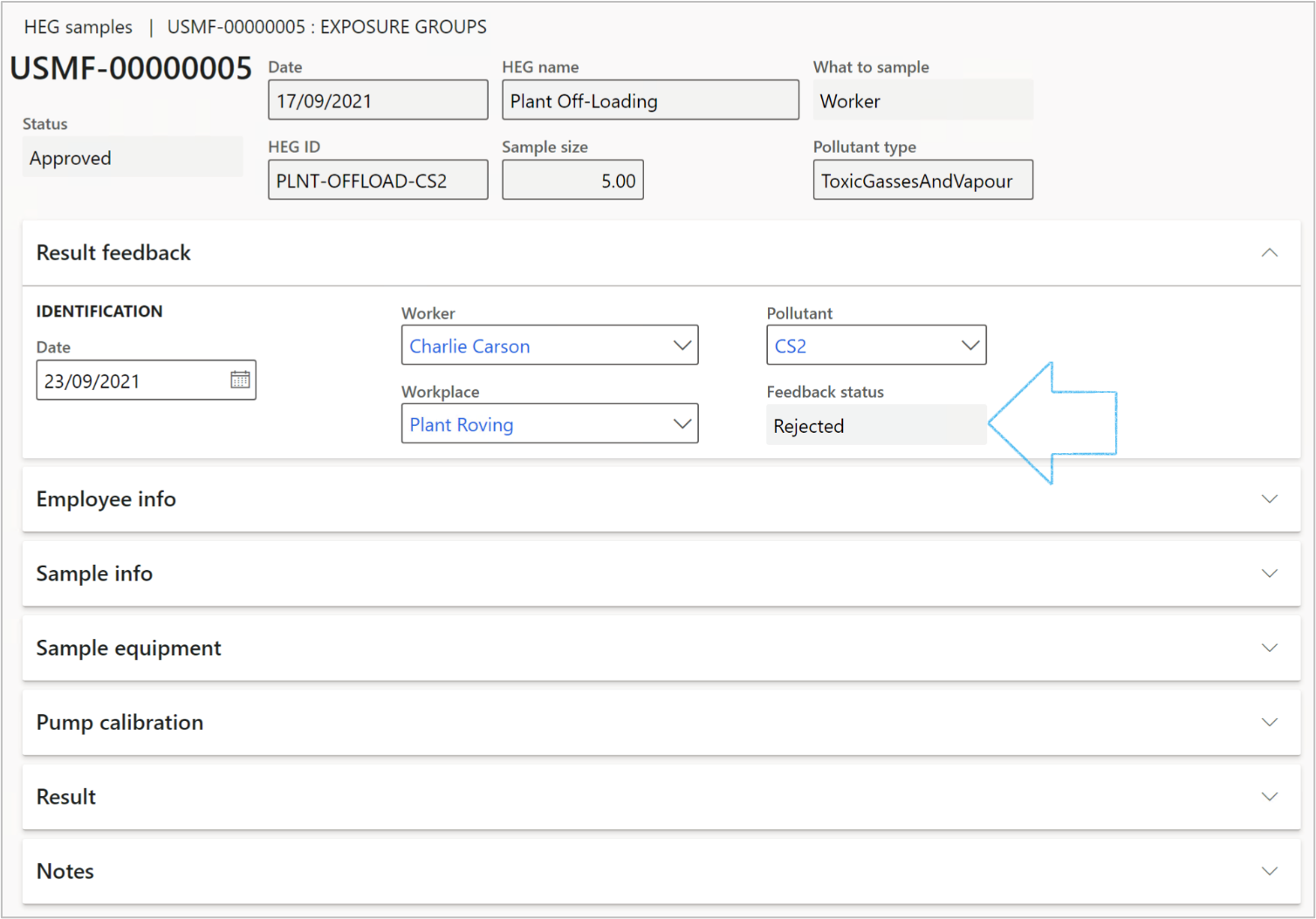

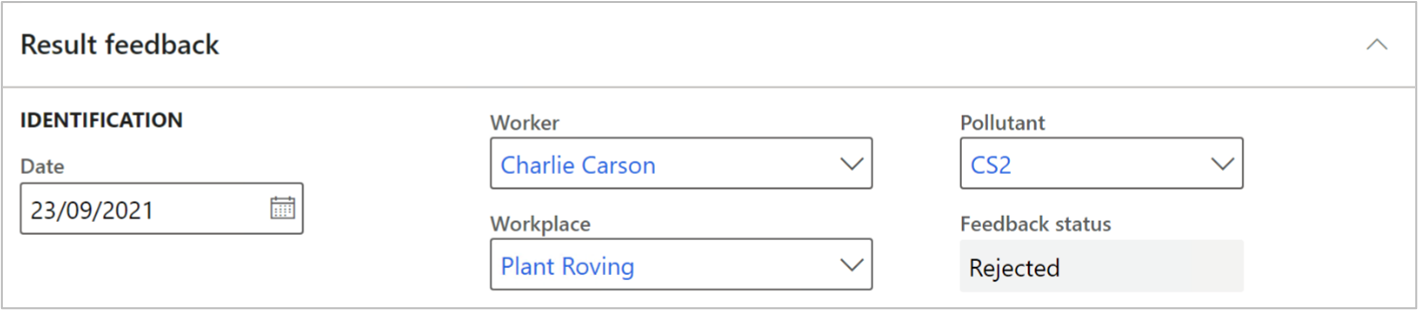

- The Result feedback Fast tab:

- Date: Date of the result feedback

- Worker: Name of the worker that the sampling was done on

- Workplace: Workplace where the sampling was done

- Pollutant: Select the pollutant from the dropdown list

- Feedback status: As selected on the Action pane

- The Additional field indicates whether this record was created by the scheduling engine, or as an additional ad-hoc record

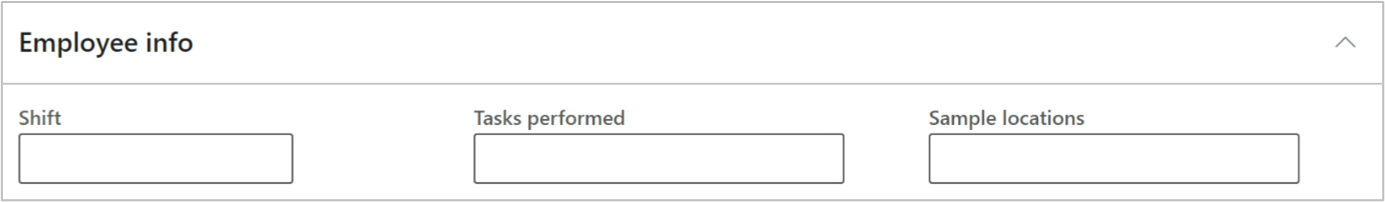

- The Employee info Fast tab:

- Shift: Enter the shift that the result was recorded on

- Tasks performed: Enter the tasks performed during the sampling

- Sample locations: Enter the locations where time was spent during the sampling

- The Sample info Fast tab:

- Sample start time: Sample period start time

- Sample end time: Sample period end time

- Sample duration (min): Calculation of sample time in minutes

- Air volume: Calculation of air volume (ml or L) = Flow rate (ml/min or L/min) x Sample time (min)

- Sampling method: Enter the method used for taking the sample

- Report number: Enter the report number of the sample

- Filter number: Enter the number of the filter

- Filter media: Enter the media used in the filter

- Analysis %: Enter the applicable analysis %

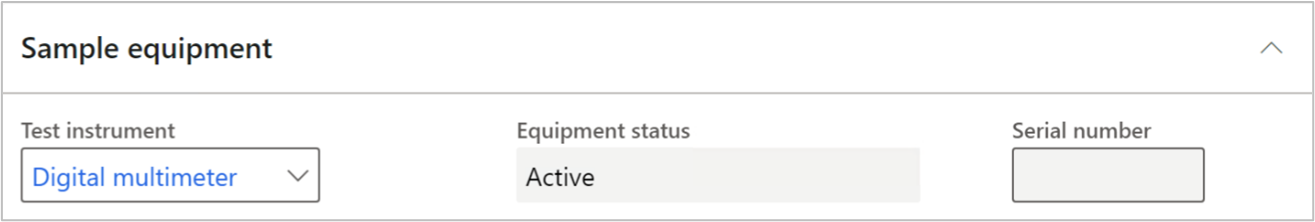

- The Sample equipment Fast tab:

- Test instrument: Select the test instrument used from the dropdown list

- Equipment status: The status of the test equipment

- Serial number: This is linked to the selected instrument

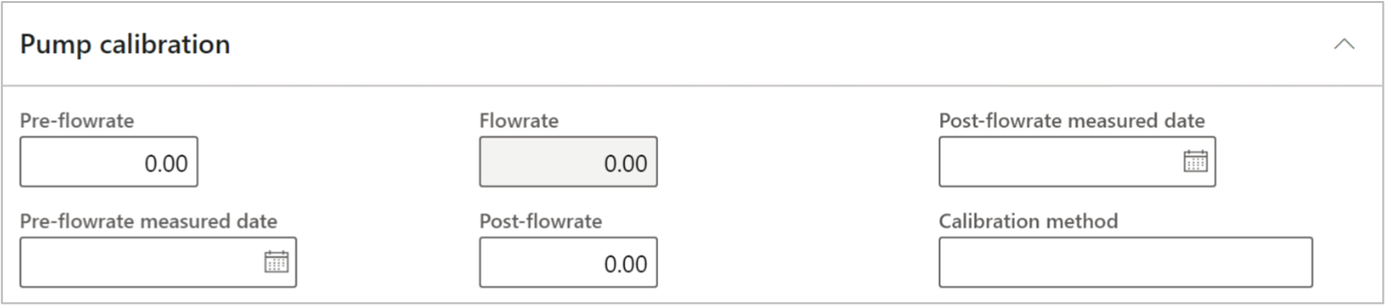

- The Pump calibration Fast tab:

- Pre-flowrate: Real value (ml/min or L/min)

- Pre-flowrate measured date: Select the date on which the pre-flowrate was measured

- Flowrate: Calculated average flowrate of the pre- and post-flowrate is used in calculations of air volume

- Post-flowrate: Real value (ml/min or L/min)

- Post-flowrate measured date: Select the date on which the post-flowrate was measured

- Calibration method: Enter the method of calibration used

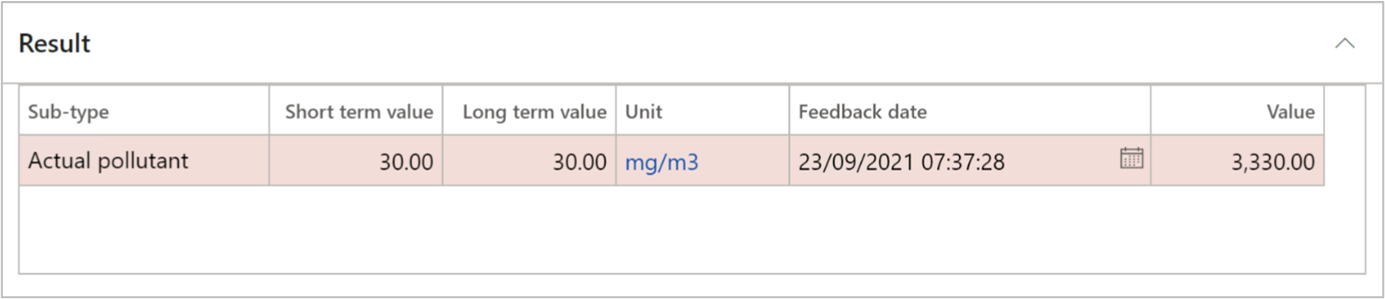

- The Result Fast tab:

- Sub-type: The sub-type as setup on the Homogeneous exposure group on the HEG, and can be one of the following:

- Actual pollutant

- Wet bulb

- Wet Bulb

- Dry Bulb

- Globe

- Velocity

- Chill Factor

- Short term value: Short term OEL value as setup on the Homogenous exposure group on the HEG

- Long term value: Long term OEL value as setup on the Homogenous exposure group on the HEG

- Unit: The unit of measure as setup on the Homogenous exposure group

- Feedback date: Select the date that the actual sample was taken

- Value: Enter the value of the sample result

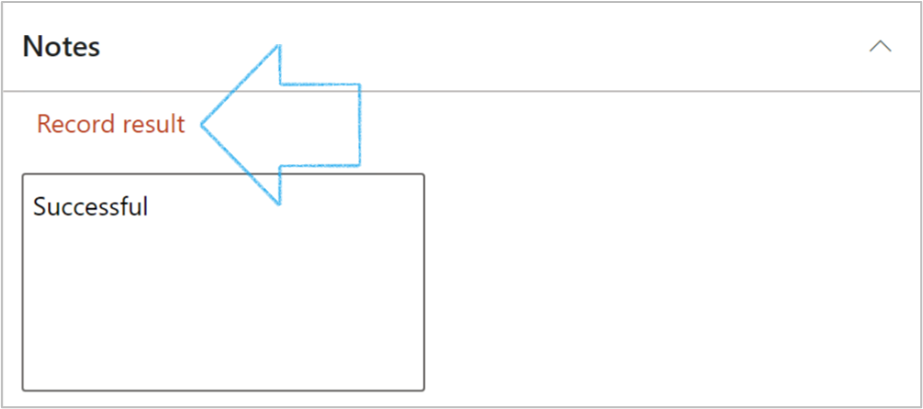

- The Notes Fast tab:

- Enter optional comments on this record

Once the feedback status on the line has been changed to Approved, the Record result button becomes active

Once the Record result button has been clicked, the buttons on the button strip become inactive

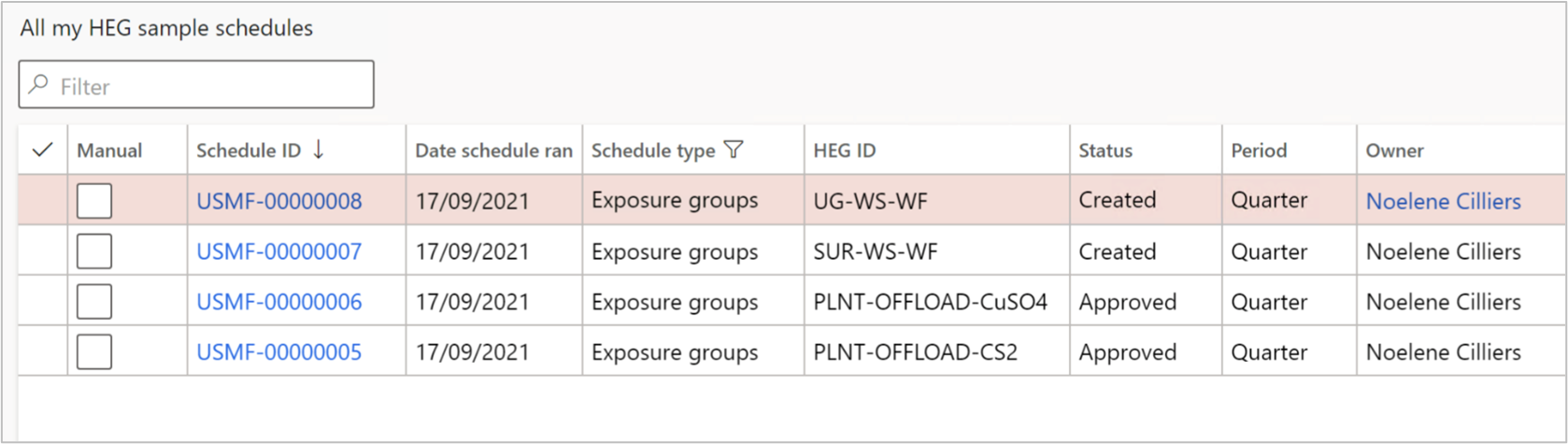

¶ Step 22: View all my sample schedules

This form shows all the sampling schedules where the owner is the current logged in user

Go to: Health, Safety and Environment > Industrial hygiene > Schedules > All my HEG sample schedules

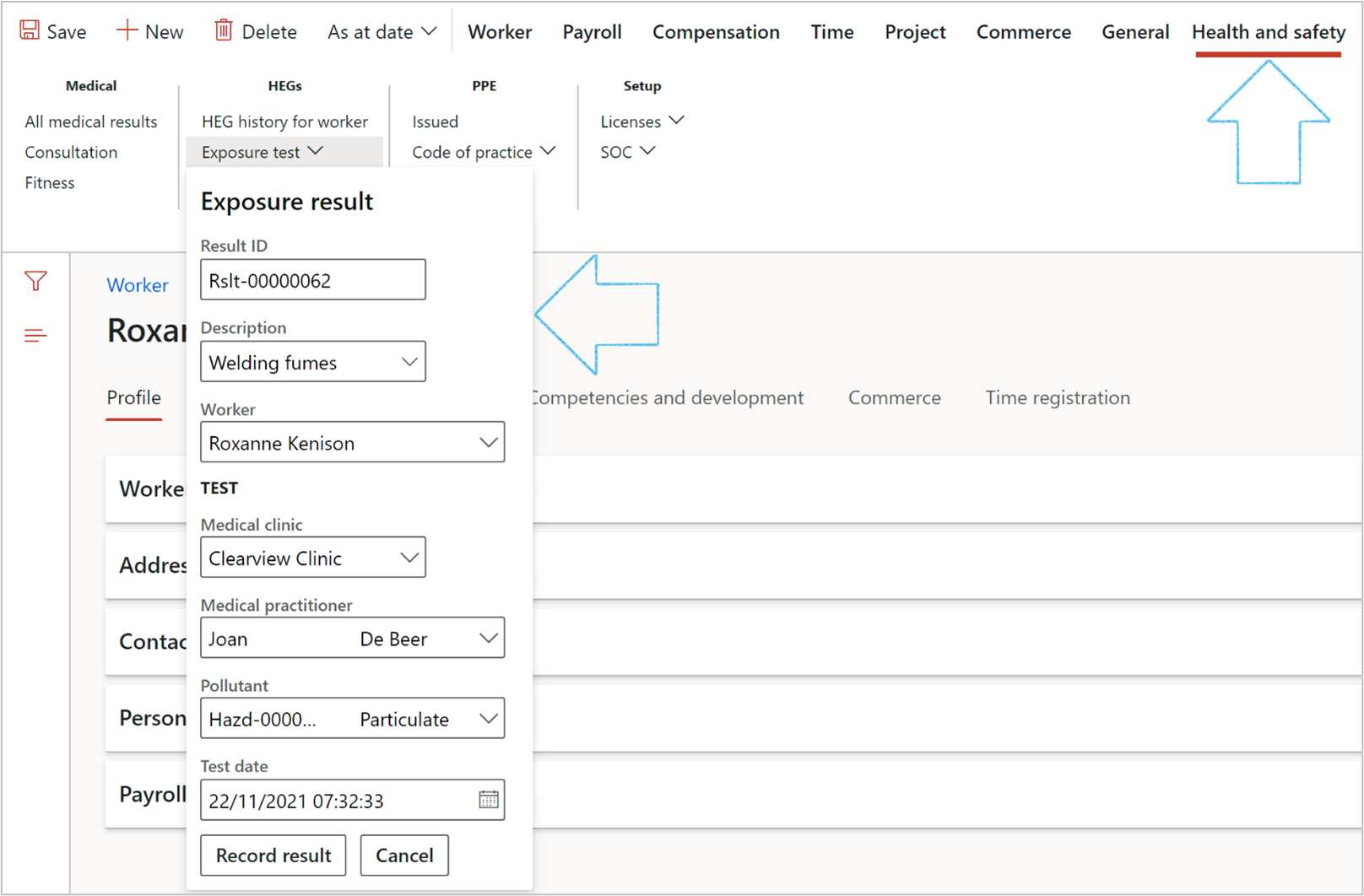

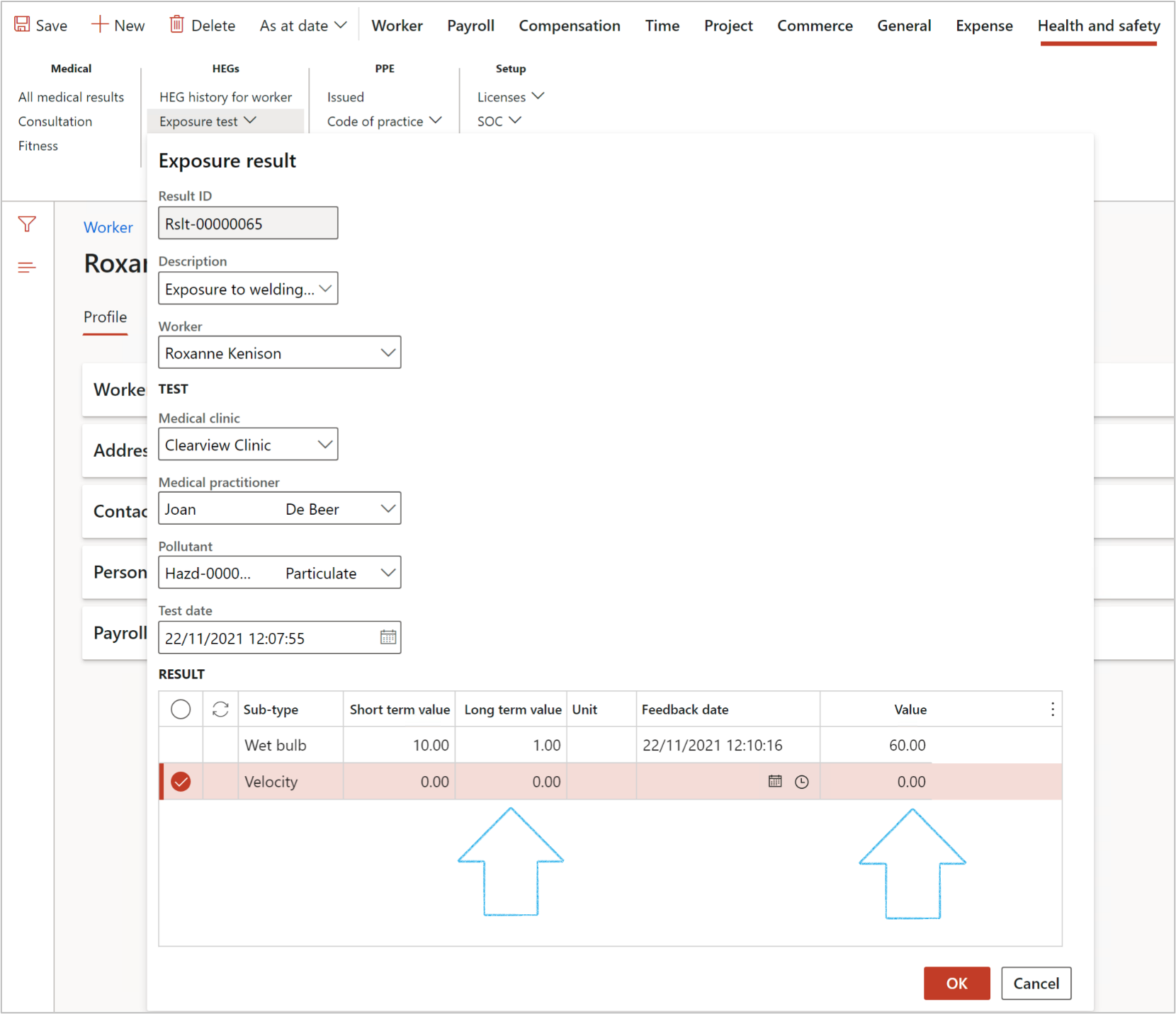

¶ Step 23: Record Exposure test result for a worker

Go to: Health, Safety and Environment > Workers

- Select the relevant worker

- On the Action pane, open the Health and safety tab

- In the HEGs group, click on the Exposure test button

- On the Exposure result dialog:

- Enter a brief Description of the exposure result

- Select the Medical clinic where the test was done, from the drop-down list

- Select the Medical practitioner who did the testing, from the drop-down list

- Select the Pollutant that was tested for, from the drop-down list

- Enter the Test date

- Click on the Record result button

- Enter the results under the Results section that opens

- Click OK

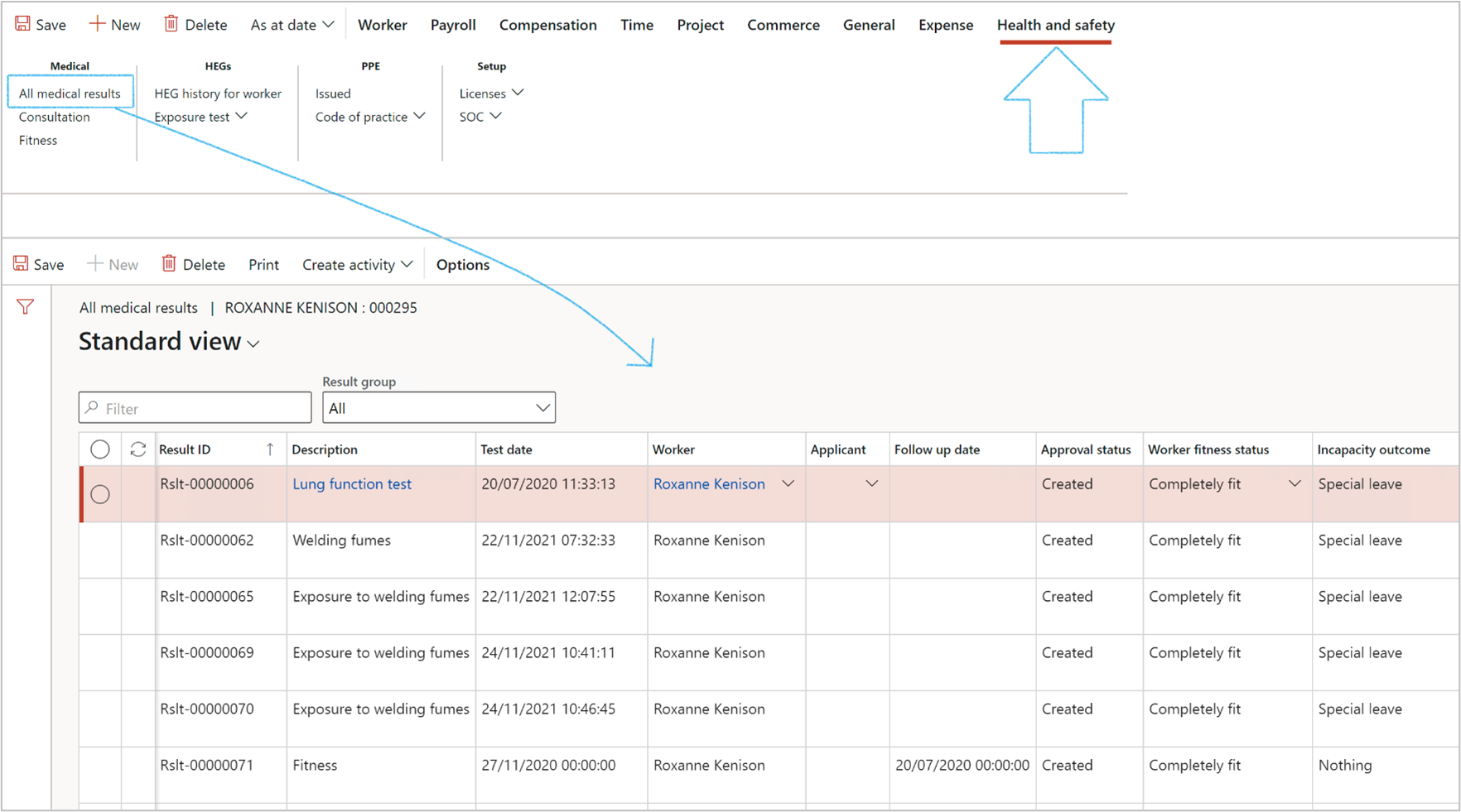

- To view these recorded results on the Worker form:

- On the Action pane, in the Medical group, click on the All medical results button

¶ Step 24: Calculation

¶ Step 24.1: Requirements for calculations

The following requirements have to be met for the exposure calculation to take place:

Go to: Health, Safety and Environment > Industrial Hygiene > All HEGs in legal entity

- The Feedback date must fall within the HEG From date and To date

2. The sample result pollutant must be the same as the HEG pollutant (On the Action pane, click on the Exposure result button)

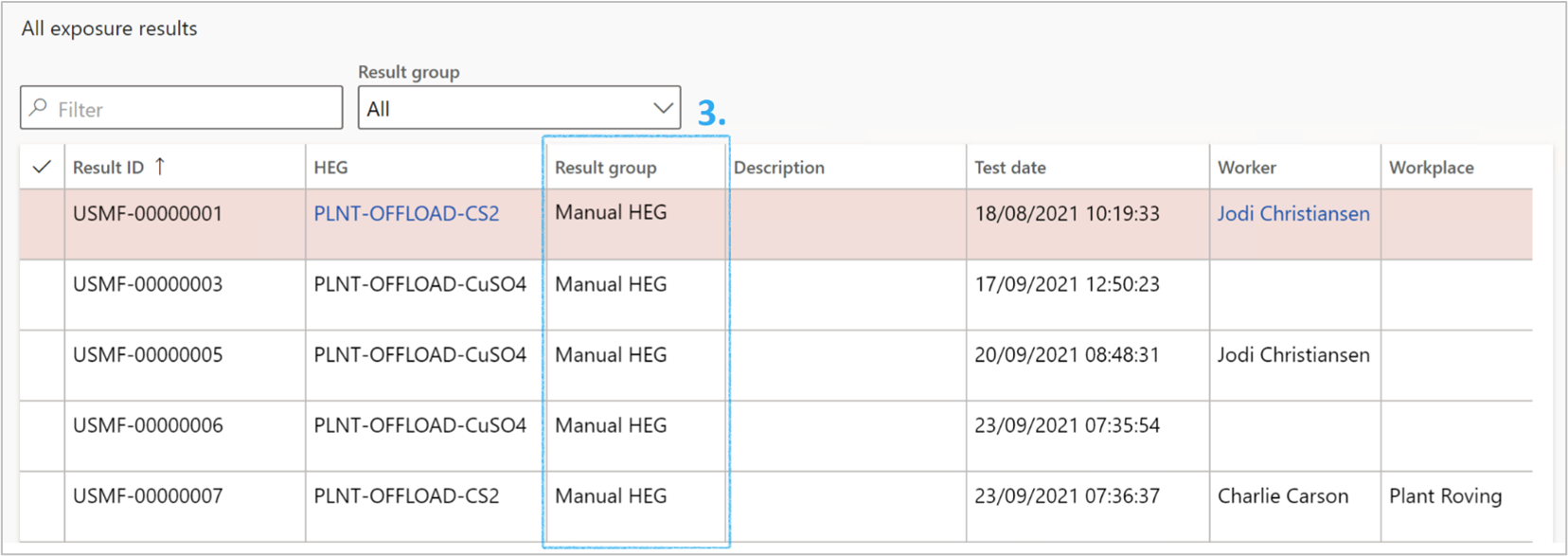

3. Exposure Result group must be Manual HEG or Scheduled HEG

Go to: Health, Safety and Environment > Industrial Hygiene > Reports and Inquiries > All exposure results

The last three columns on the inquiry are for radiation results: (Indicated as Individually measured on the Pollutant)

- Individual minimum

- Individual maximum

- Individual average

4. The sample Feedback status must be Recorded (See Step 19.3 the Notes Fast tab)

5. The sample Schedule status must be Completed

6. The sample result must have the same Result ID as the sample

Go to: Health, safety and Environment > Industrial Hygiene > Schedules > All HEG sampling schedules

- Select the relevant Approved schedule

Go to: Health, Safety and Environment > Industrial Hygiene > All HEGs in legal entity

- Select the applicable HEG

- On the Action pane, click the Calculate exposure button

- Select one of the three options to calculate the exposure limit based on results for:

- For workers (via their HR position) in the HEG

- For workplaces being controlled by the HEG

- For workers and workplaces

¶ Step 24.2: Calculate exposure

To calculate a new exposure band, click on the Calculate exposure button A

The HEG is now categorized into a classification band to determine the homogeneous exposure group within that activity area

The data used for the calculation will depend on the following selection:

- The selected HEG

- Only approved results (rejected results will be excluded)

- The test results based on the Worker, Workplace or Both (by selecting from the dropdown list B)

- Test done between the dates specified in C

The system will then update the following:

- Last date calculated D

- Based on D

- Calculated value D

- Results Id E

- Date E

- Current band E

- Previous band E

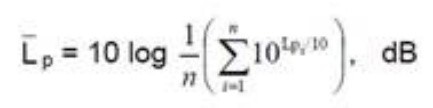

The calculated value is calculated as follows:

- The 90th percentile calculation is used for airborne pollutants and thermal stress

- Average decibels calculation for noise

When the Exposure result button is clicked, the following checks are done:

- Is there a schedule with a Period of Day, and whether is it a Manual schedule for that specific HEG, for the current day

- If a schedule exists, then the sample will be created and linked to that schedule

- If no schedule is found, a schedule as well as a sample will be created

¶ Reporting

¶ Step 25: All test results (Inquiry)

Go to: Health, Safety and Environment > Industrial hygiene > Reports and Inquiries > All exposure results

- Select the Result group that you want to view from the drop-down list

.png)

- To export the inquiry to Excel: On the Action pane, click the Open in Microsoft office button and select the required option from the dropdown list

_1.png)