¶ Introduction

A typical scenario of any Safety and Asset management strategy and a key element of the ISO 55000 standard is the organization of your objects (assets/equipment) and locations, normally into a hierarchy of parents and "dependant" children.

- In general, an object is the lowest maintainable (or replaceable) element that users are concerned with. Equipment, facilities or assets that the organization is responsible for to maintain and or manage.

- The locations are grouped into a structure and is simply the hierarchy of the Locations of an enterprise. Campus – Building – Floor – Room – Plant is a simple example. No matter the hierarchy users develop for an organization, it is the “tree” of where all your objects are. All objects are placed at some level in the tree.

Users should add hazards to objects and location records so that when for example a work order is created on an asset or location, the appropriate safety information is available. The safety information defined in the object and in the location application might be added to a safety plan or added directly to the work order. In addition the hazards on objects and at locations will be used when recording a safety incident (event) or to highlight Confined space and/or Asbestos hazards.

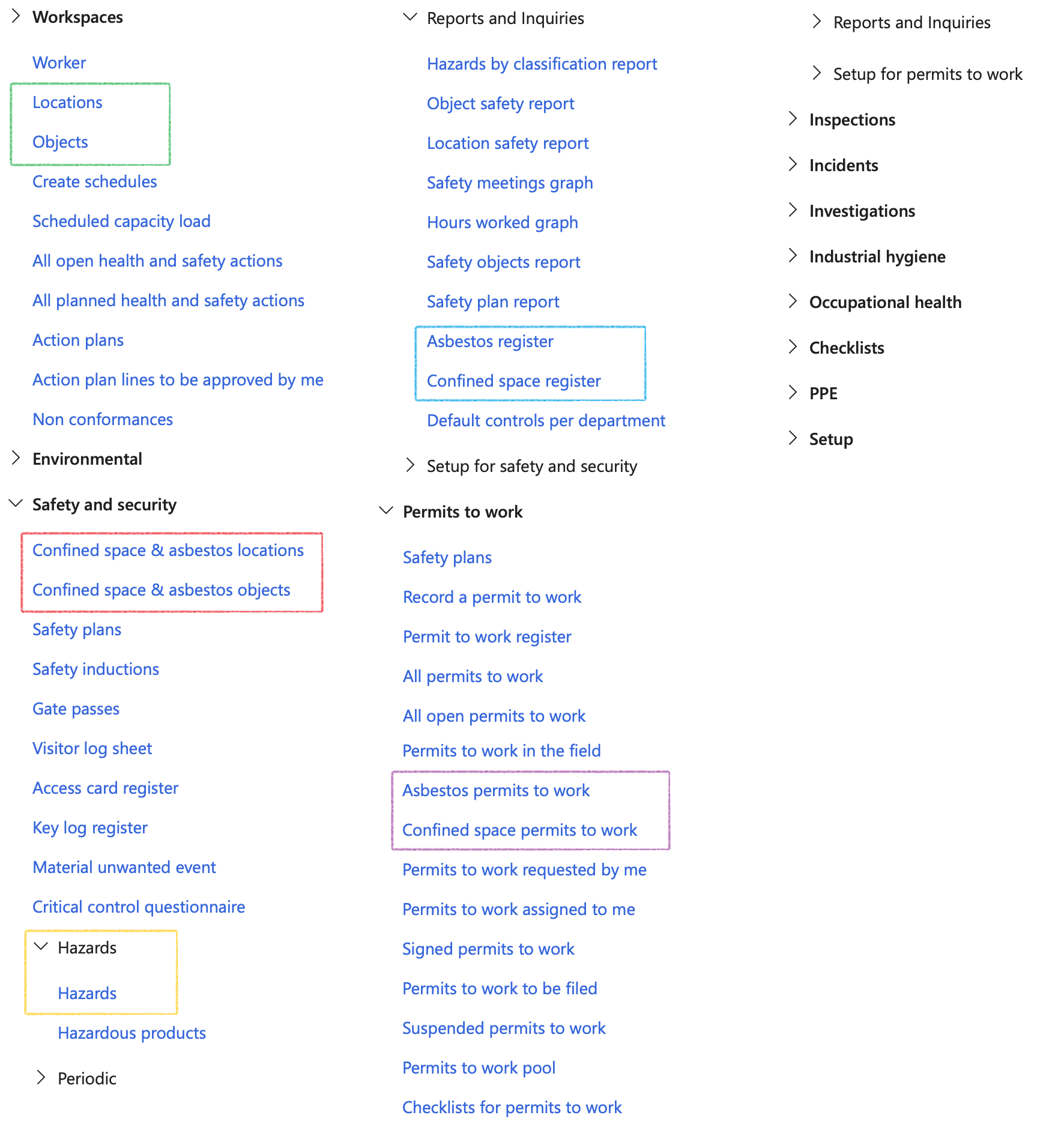

¶ Navigation

¶ Specific setups

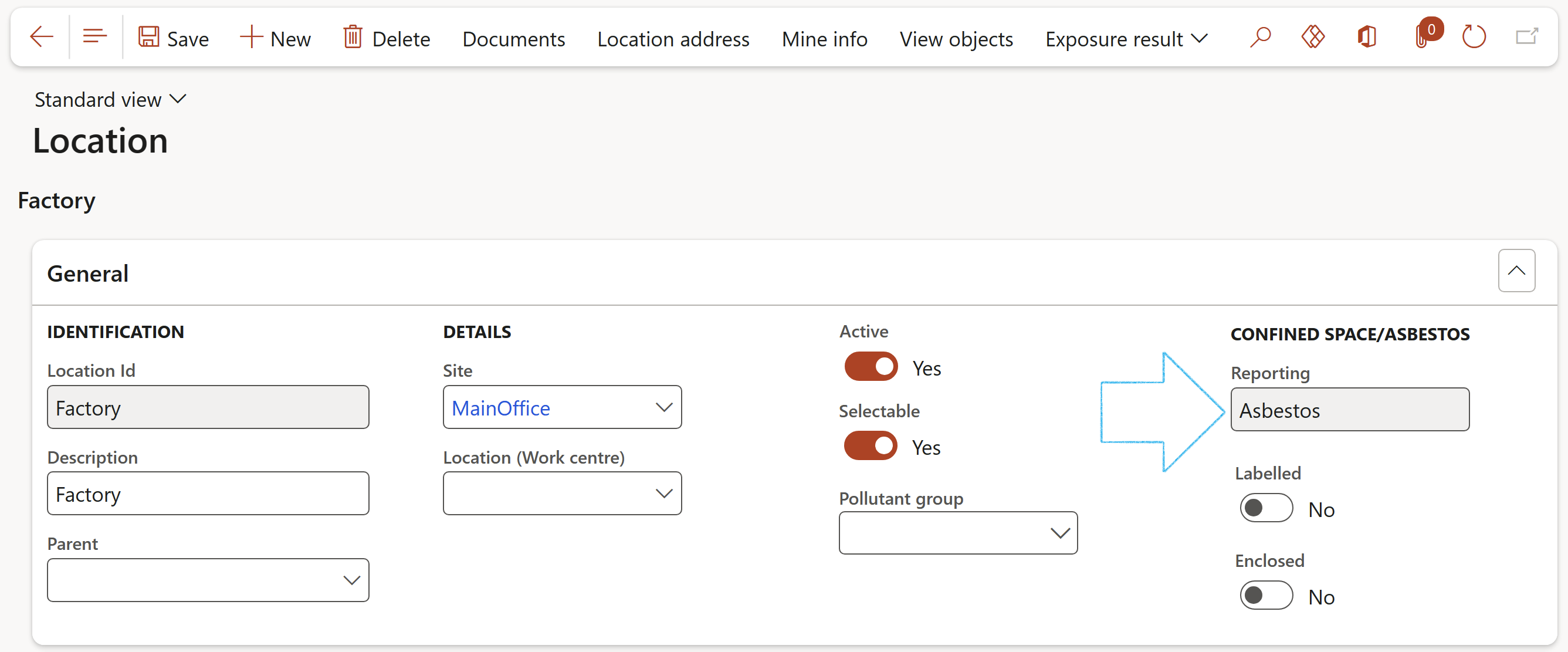

¶ Step 1: Setup locations

A location is a place where objects are used, stored, or repaired. You can use the Locations list page to view, add, or edit information about locations, service addresses, or hazards.

Go to: HSE > Location

- Select the relevant Location

- Expand the General Fast tab

- The default value in the Reporting field is None. Once a Reporting value is selected on the Hazard, that value will replace the existing value here on this form via the Applicable areas Fast tab on the Hazard form

| Reporting filter selected |

Visible fast tabs on the form |

|

| None |

|

|

| Confined space |

|

|

| Asbestos |

|

|

| Both |

|

|

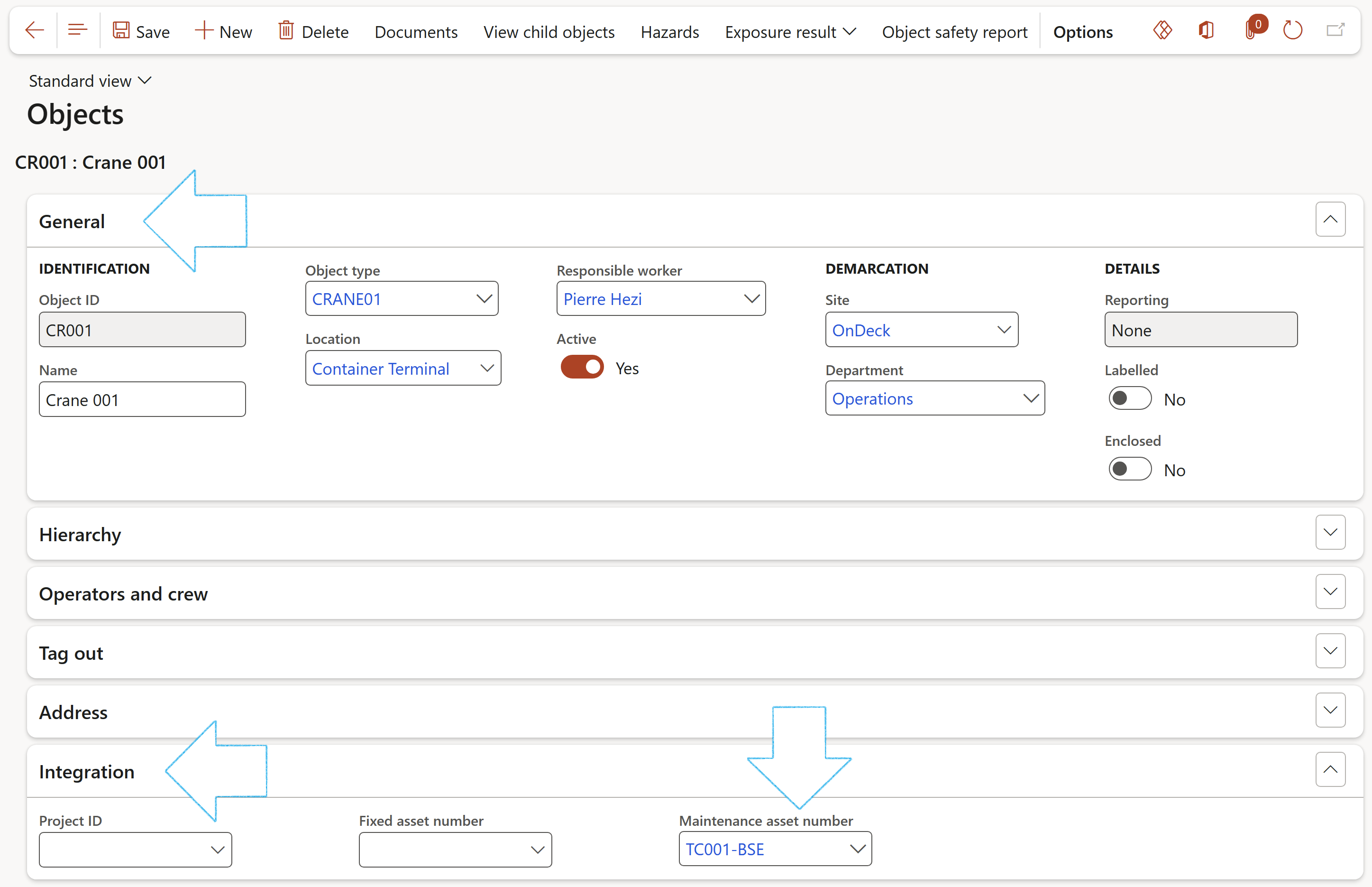

¶ Step 2: Setup objects

Keeping an electronic/digital register of compliance obligations with a detailed overview of your objects (assets/equipment) is one of the wisest things an enterprise can do. Thus allowing visability of your objetc’s history and upcoming activities in one place.

Go to: HSE > Objects

- In the Action pane, click on the New button

- Under the General Fast tab, enter a Name for the object

- Select the relevant Object type from the dropdown list

- Select the Location where the object will be used, from the dropdown list

- Select the worker Responsible for the object, from the dropdown list

- Select the relevant Site from the dropdown list

- Select the relevant Department from the dropdown list

Physical assets degrade over time with constant use. Maintenance scheduling is essential to prevent breakdowns and prolong the operating life of the asset. An accurate asset register will help your organization plan and execute the maintenance work required.

Heavy machinery and vehicles often have strict oversight and regulations. Safety object registers help your organization stay compliant as they provide evidence that you are following recommended practices and comply to legal obligations.

Both these sets are maintained. But to provide an integrated reporting and compliance view these two sets of master data can be mapped on a one-to-one basis.

- Expand the Integration Fast tab

- Select the relevant Maintenance asset number from the dropdown list

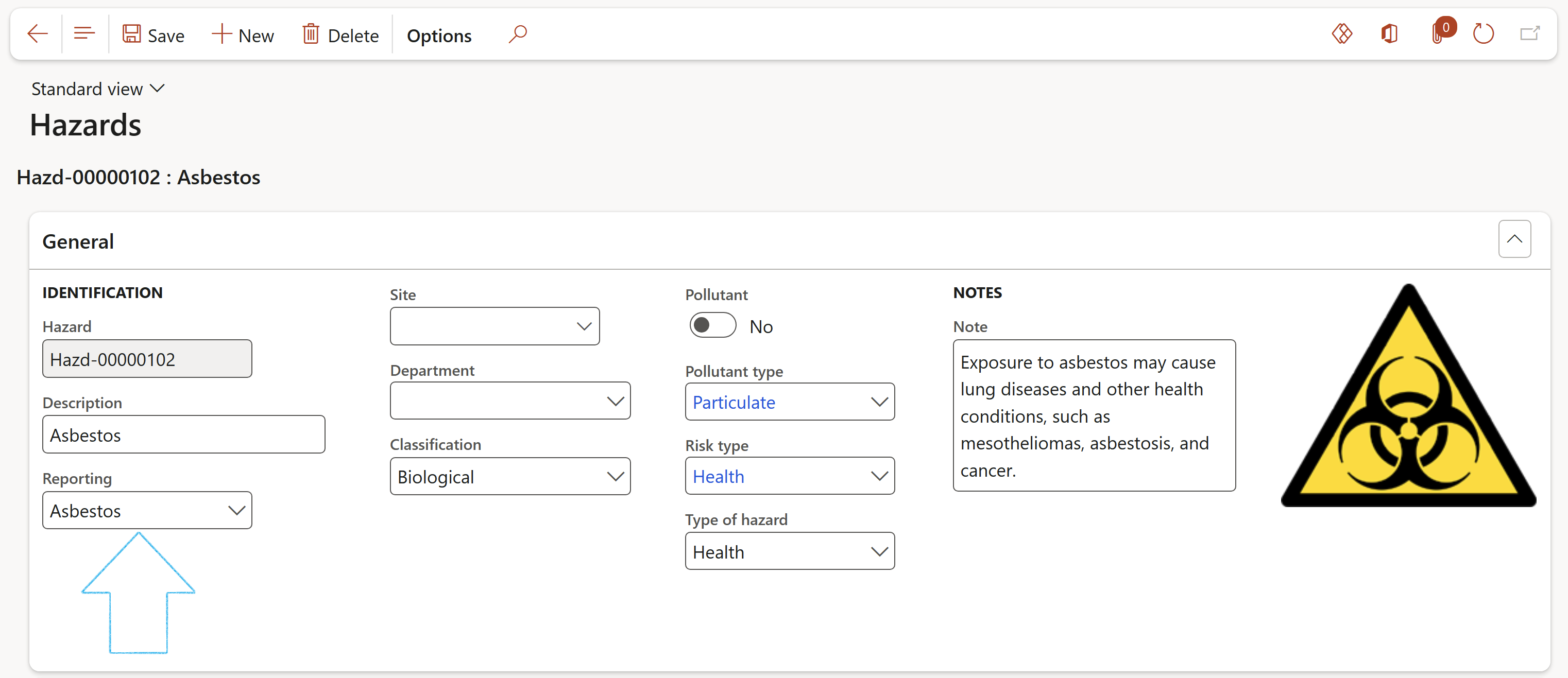

¶ Step 3: Create hazards with reporting type

A hazard is a source or a situation with the potential for harm in terms of human injury or ill-health, damage to property, damage to the environment, or a combination of these.

Hazards at work may include noisy machinery, a moving forklift, chemicals, electricity, working at heights, a repetitive job, or inappropriate behaviour that adversely affects a worker’s safety and health.

Where as an unwanted event is a situation or condition where there is a loss of control of the hazard that leads to harm.

Go to: HSE > Safety and security > Hazards > Hazards

- In the Action pane, click on the New button

- Under the General Fast tab, in the Reporting field, select whether the hazard is Asbestos or Confined space (the default value is None)

Use the classification field to display different types of pictograms.

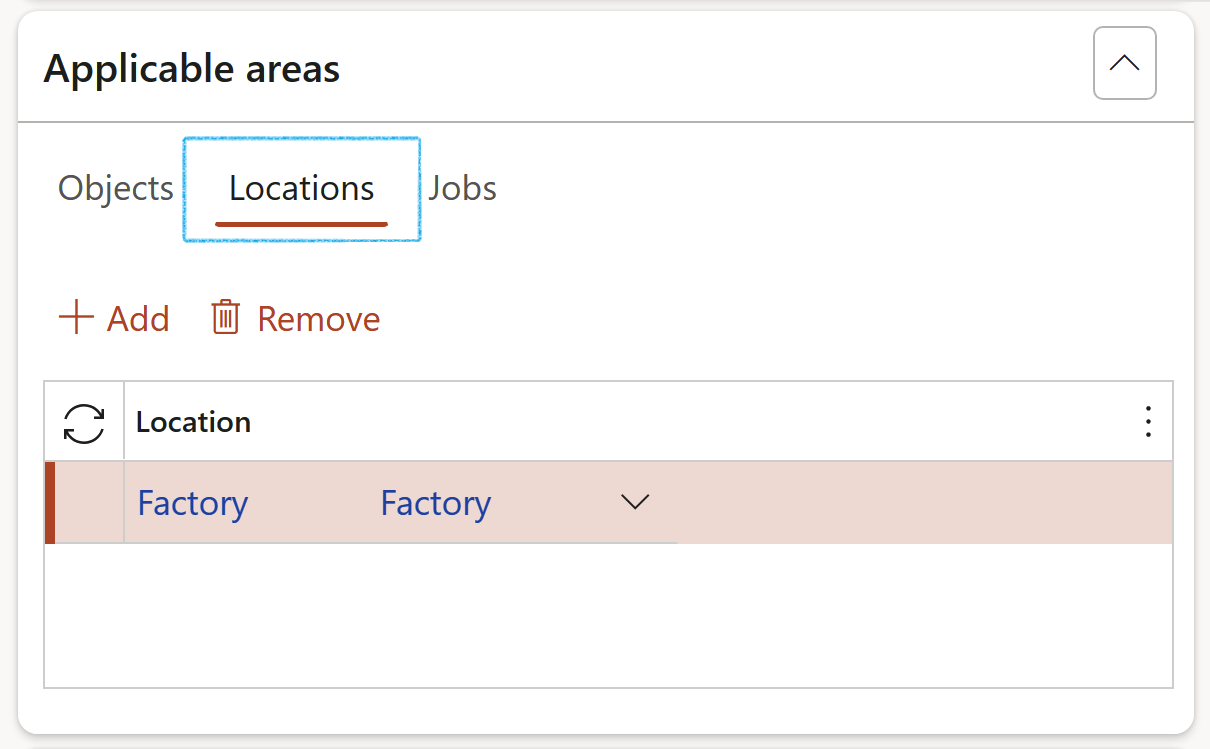

¶ Step 3.1: Applicable areas Fast tab

- Expand the Applicable areas Fast tab

- Open the Locations Index tab

- In the Button strip, click on the Add button

- Select the relevant Location from the dropdown list

The value selected in the Reporting field on the Hazard form will update the Reporting value on the Location selected on the Hazard form

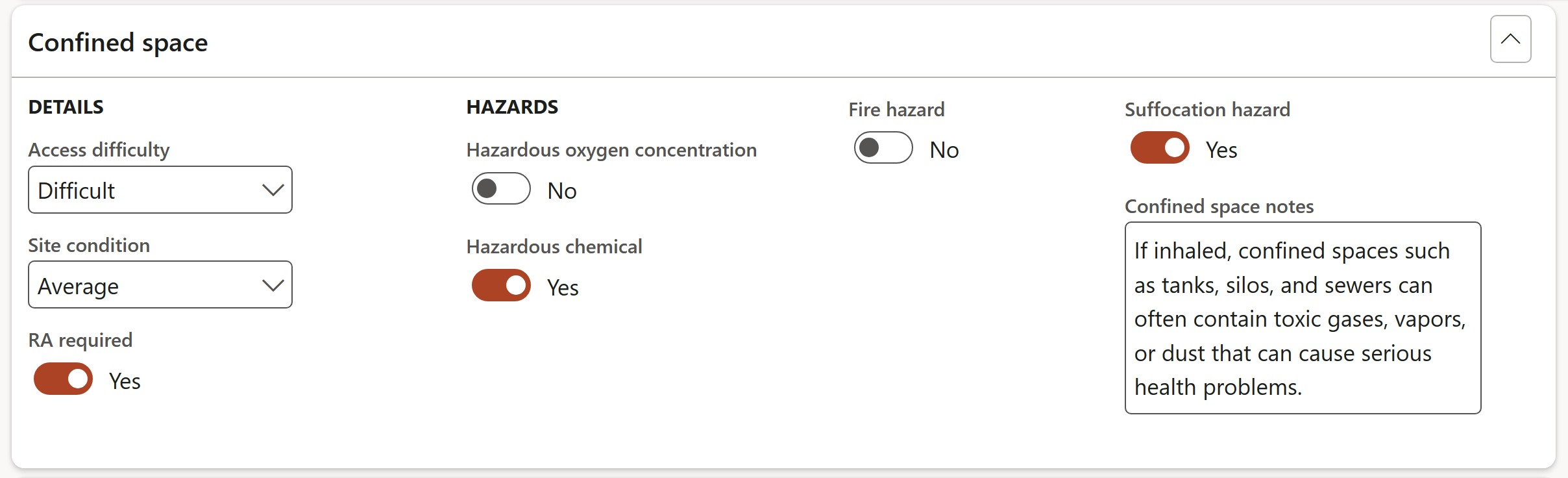

¶ Step 3.2: Confined space Fast tab

- On the Location, expand the Confined space Fast tab

- In the Access difficulty field, select the level of difficulty for a person to enter the space

- In the Site condition field, specify the condition of the space

- In the RA required field, indicate whether a Risk assessment is required

- In the Hazardous oxygen concentration field, indicate whether the space has an oxygen concentration outside of the safe oxygen range

- In the Hazardous chemical field, indicate whether there is a hazardous chemical present that may cause impairment, loss of consciousness or asphyxiation

- In the Fire hazard field, indicate whether there is a substance present that may cause a fire or explosion

- In the Suffocation hazard field, indicate whether there is a free flowing solid or possible rising level of liquid that may cause suffocation

- In the Confined space notes field, enter any additional notes concerning the confined space

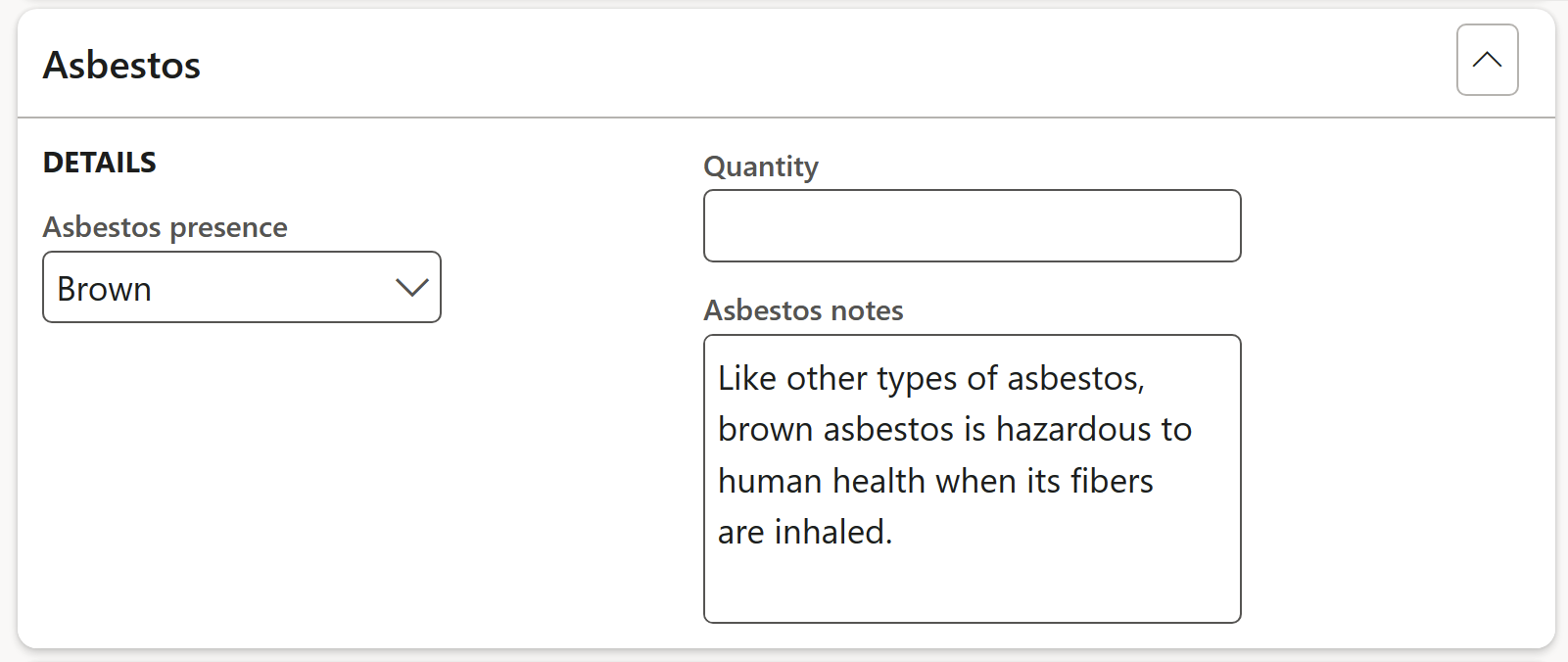

¶ Step 3.3: Asbestos Fast tab

- On the Location, expand the Asbestos Fast tab

- In the Asbestos presence field, specify the type of asbestos present

- In the Quantity field, enter the quantity of asbestos present

- In the Asbestos notes field, enter any additional notes concerning the asbestos

If the Asbestos presence field is not populated with a value, the location will not be displayed on the Asbestos register

¶ Daily use

¶ Step 4: Confined space

Confined spaces pose dangers because they are usually not designed to be areas where people work. Confined spaces often have poor ventilation which allows hazardous atmospheres to quickly develop, especially if the space is small.

Confined spaces are commonly found in vats, tanks, pits, pipes, ducts, flues, chimneys, silos, containers, pressure vessels, underground sewers, wet or dry wells, shafts, trenches, tunnels or other similar enclosed or partially enclosed structures, when these examples meet the definition of a confined space in the Work Health and Safety Regulations.

Hence, organizations are required to keep track of confined space entries in a register.

A confined space does not include a mine shaft or the workings of a mine.

¶ Step 5: Asbestos

Asbestos becomes a potential risk to health if fibers are suspended in air and breathed into the lungs. Breathing asbestos fibers into the lungs can cause a range of diseases, including mesothelioma, lung cancer and asbestosis.

When asbestos is identified in a workplace, you need to create an asbestos register.

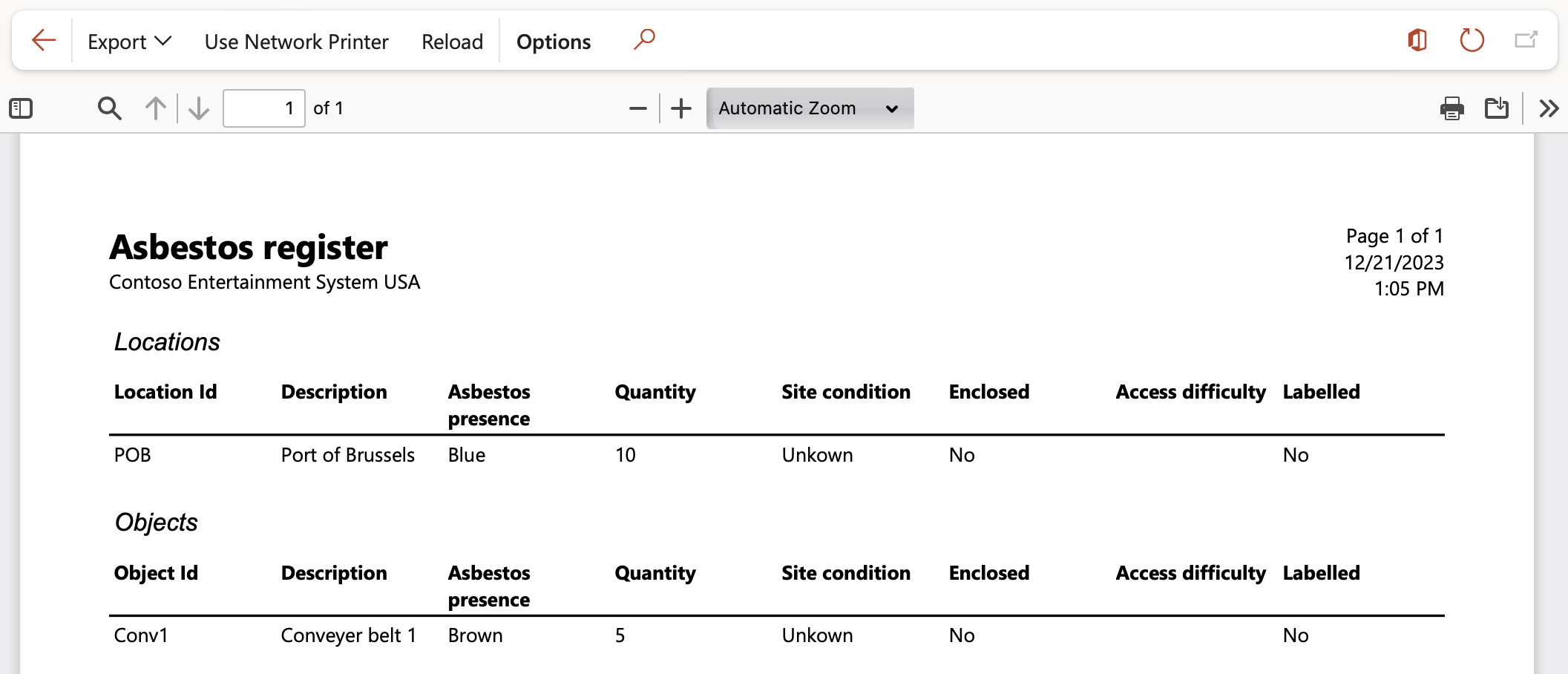

The Asbestos register must be kept current and includes:

- The location of the asbestos

- The likely source of asbestos that is not fixed or installed

- The type of asbestos containing material

- Whether the asbestos containing material is friable or non-friable

- The condition of the asbestos-containing material

- Whether the asbestos-containing material is likely to sustain damage or deterioration

- Details of the location and likely source of asbestos that is not fixed or installed in relation to all inaccessible areas that may contain asbestos

- So far as possible detailed information about activities likely to be carried out in the workplace that are likely to damage or disturb the asbestos

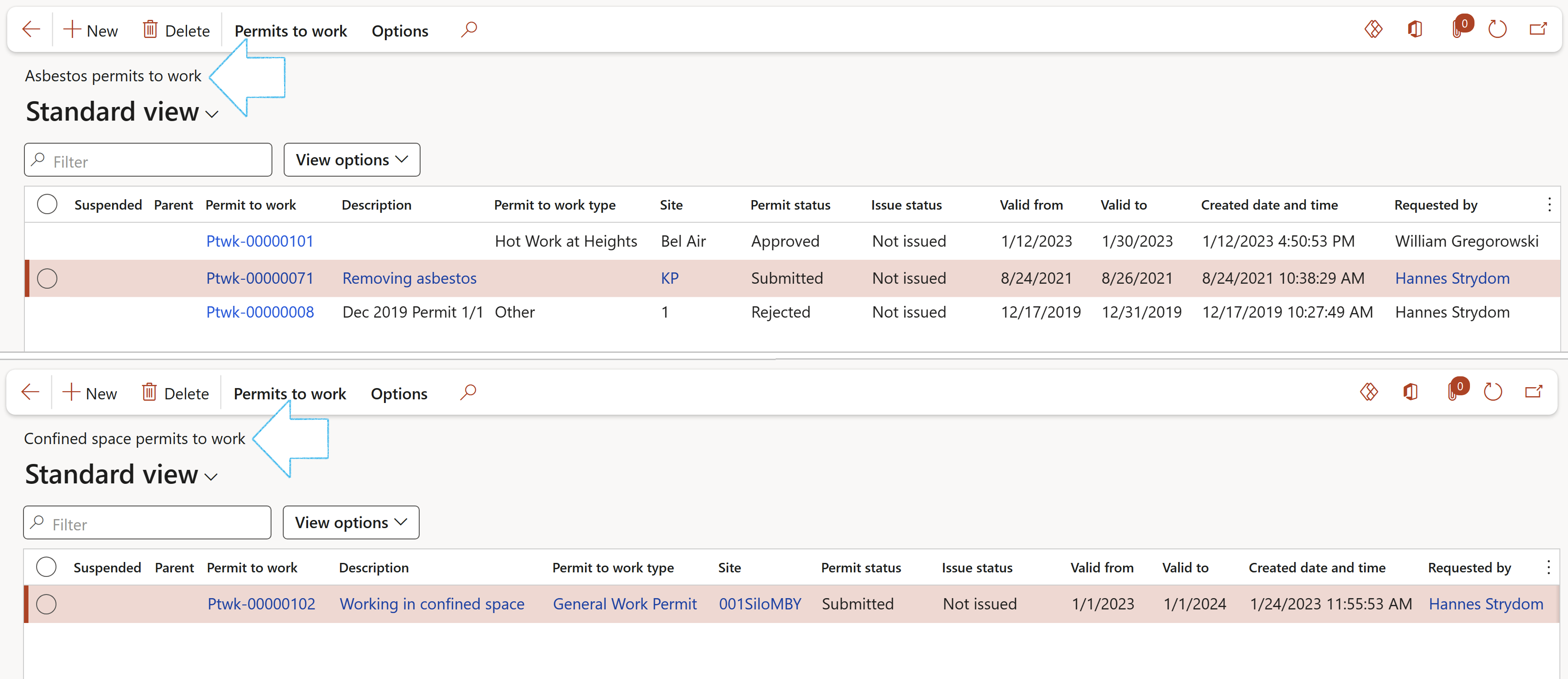

A key tool in mitigating worker exposure and injuries is the formal Permit to work module inside HSE 365.

As the permit to work identifies Hazards, dedicated menus exist to focus in on permits to work that related to confined space entry as well as possible asbestos areas.

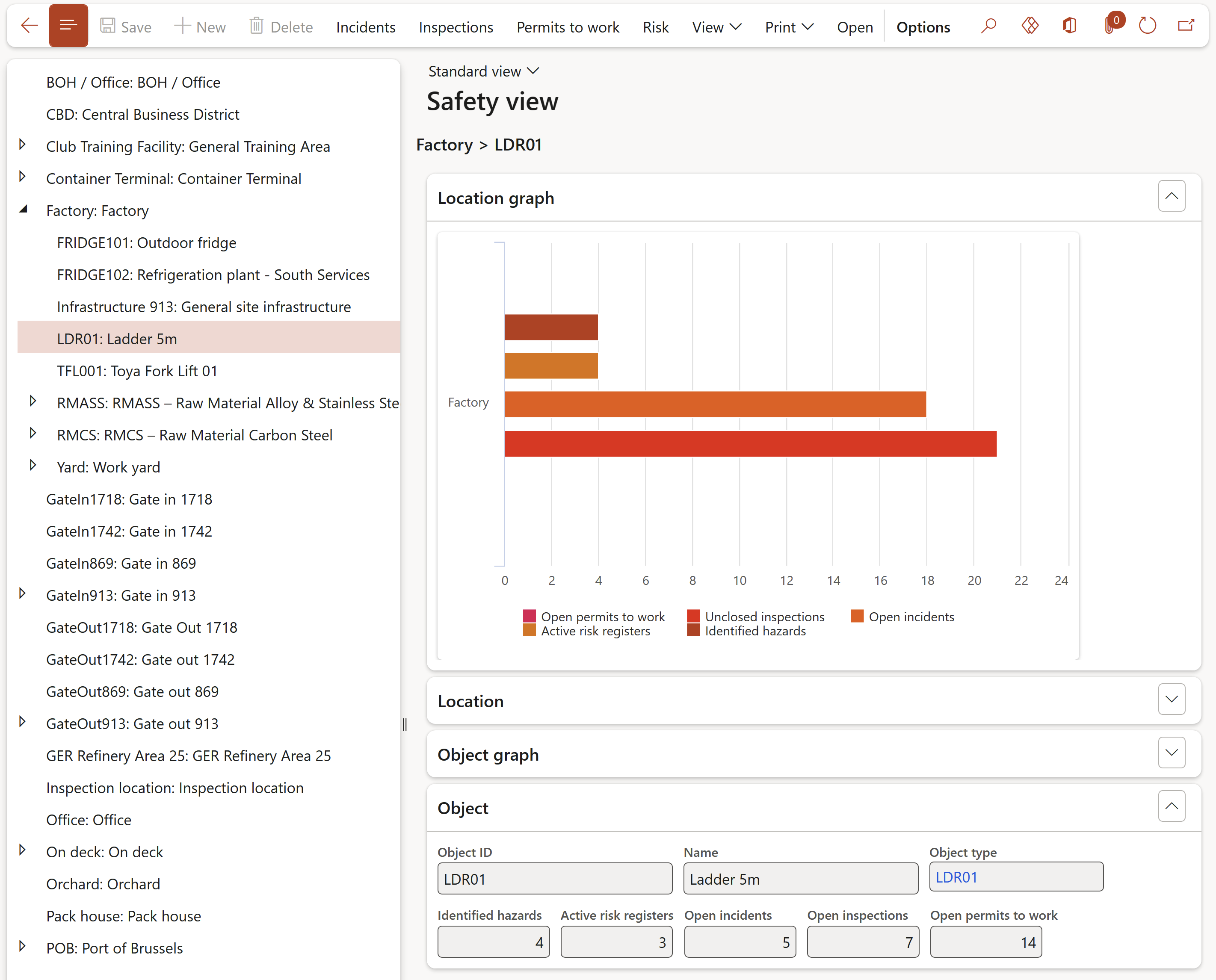

¶ Dashboard

It all comes together in HSE 365 with the Safety tree view workspace. To the left a tree view is presented. Starting with locations (parent) and related child objects. To the right detail of safety bits are presented per location and per object.

Go to: HSE > Workspaces > Safety view

¶ Reports

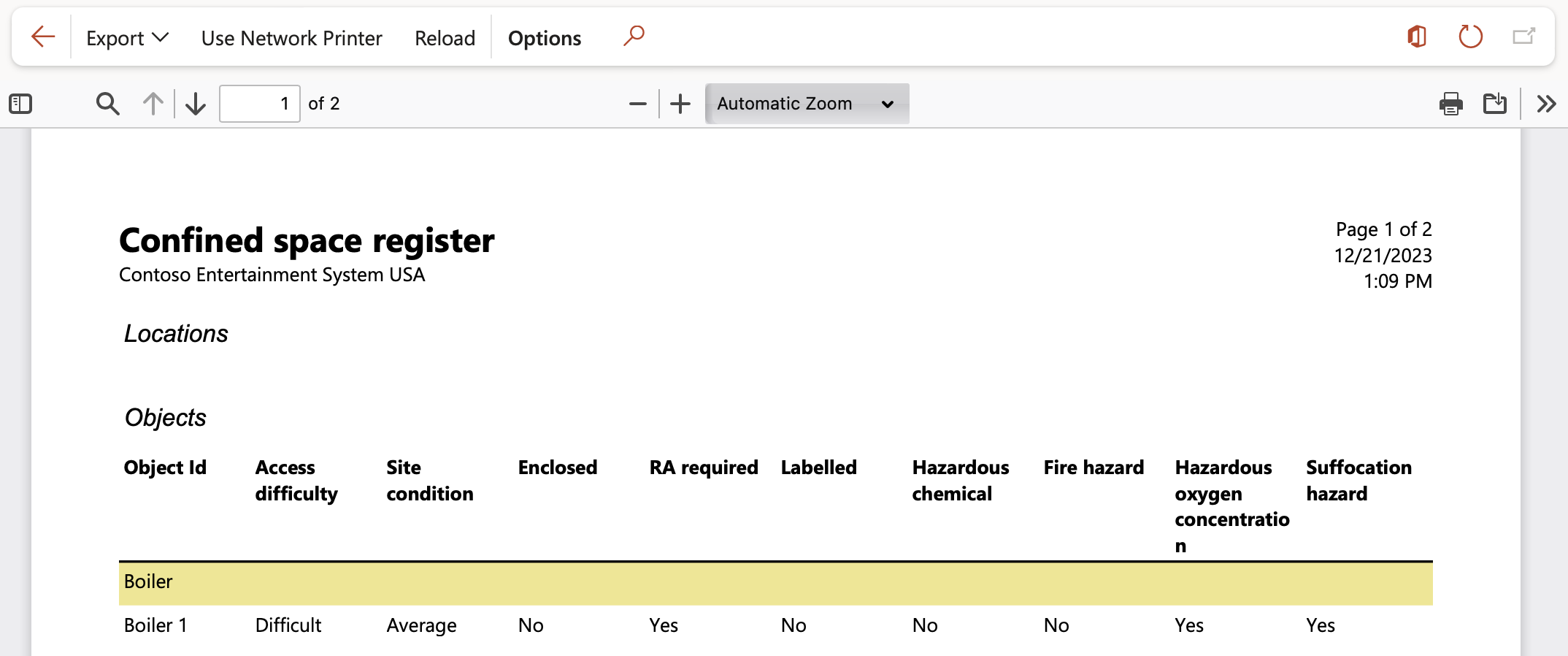

The Asbestos register and the Confined space register can be printed:

Go to: HSE > Safety and security > Reports and Inquiries > Asbestos register

Go to: HSE > Safety and security > Reports and Inquiries > Confined space register